Log Cabins are not built like a shed, at least the good ones aren’t. Especially when it comes to the cabins’ base requirements.

What I mean by this is;

Sheds: When a shed is installed the floor is placed down first, the walls go on top of it and the build is continued.

Log Cabins: With the majority of log cabins, the cabin is first built and the floor goes in afterwards and sits within the cabin and is not an integral part of it. The floor system acts as a ‘floating floor’ and should not actually touch the cabin walls. Despite this, the floor joists may touch. More often than not, the joists attach to the log cabin foundation beams.

Foundation Beam

All our cabins are built around the perimeter of a base and it is prefered that it is built on a foundation beam.

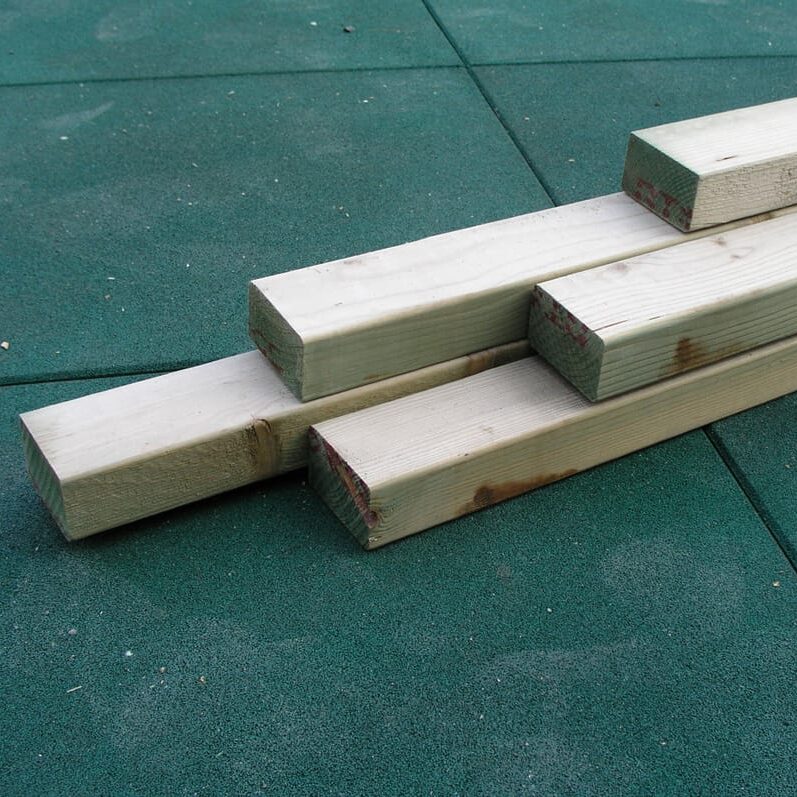

As standard we supply 70mm x 44mm tanalised beams. We supply these to go around the perimeter of the building, sitting between the first log and the base.

Using these gives your first layer of logs protection from sitting directly in any water. If you would like something a little better we also have, as an option, profiled foundation beams.

Tanalised foundation beams. We supply these with all our cabins. They go in between the base and the first log around the perimeter of the cabin.

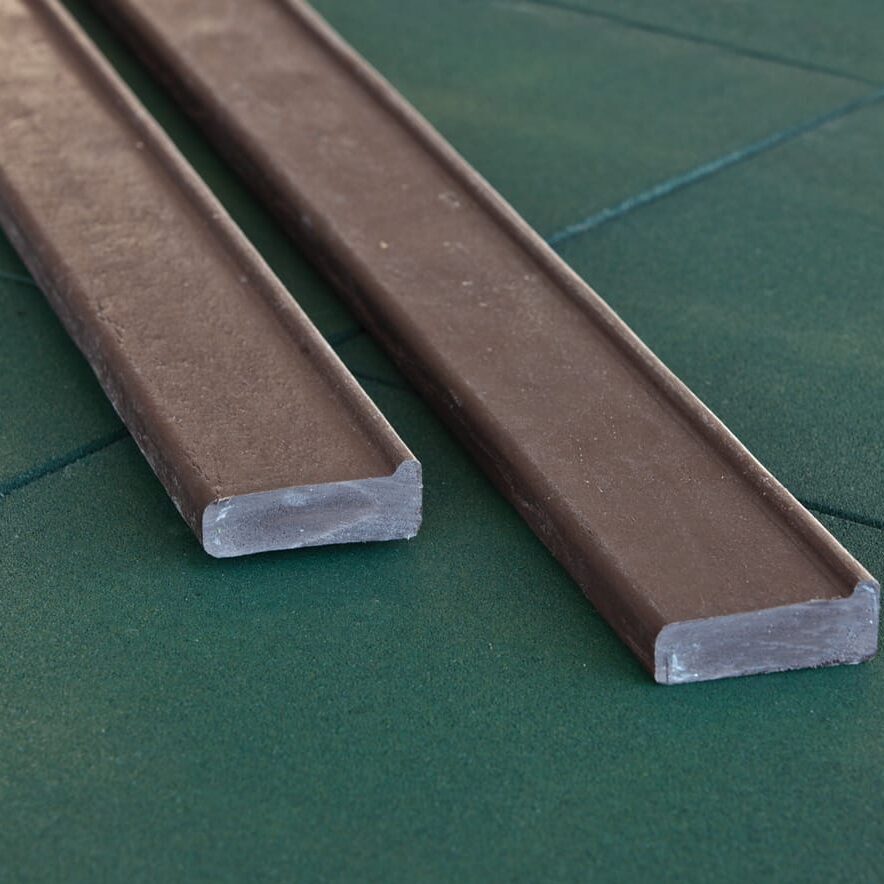

These are profiled beams. They allow any water to flush away from the first log. Available in tanalised and hardwood.

The same as the ones above but these ones consist of a composite material and never, ever rot.

The foundation beam runs around the perimeter and underneath the first log, acting as sacrificial timber. They ensure the first log stays away from any wet.

The Perimeter of your Log Cabin

Understanding the above you will realise that all of the weight is on the perimeter of the cabin.

When constructing a base, definitely consider this. Sadly, I’ve been to several fits where the centre of the base is great but has chipping and drooping on the edges. Not to mention removing all the shuttering as all the concentration had been placed on the majority of the base with an eye to shed building.

The greatest strength for a log cabin base should be within the perimeter. This is where all the weight is.

Why do you need a level base for a log cabin?

Our Log Cabins are extremely precise things. Additionally, to mill the timber, we use the best machinery. As a result, there is little tolerance. They are designed for each log to sit directly on top of one another. Then, they interlock in the corners via corner connection and the tongue and groove connection along the log. They withstand vertical forces, however cannot withstand any lateral forces.

It is quite often tempting for a landscaping/building company. This is because they are used to patios, adding a slight incline to the base to help with drainage. They tend to do this without consultation, and chuffed to tell you that you have a 2 degree incline!

This is really not very helpful as, in effect, you’ll be building your cabin on a slope, subjecting it to lateral force from gravity. A cabin cannot handle gravity and the subsequent sideways force it puts upon it from sloping.

The end result will be a buckling and warping building. In addition, it will feature split and strained logs over time and inevitable tears as you see your lovely building disintegrate over time.

The biggest thing though about an unlevel base is that it makes it hard to put the thing together. Fully expect all sorts of problems with a wonky base:

- The logs won’t seat properly.

- The windows or doors will be on the wonk.

- The apex will not sit flush with the upper wall leaving a gap which you will then have to trim to look anything, either with a planer or bits of wood stuck on it.

- The roof boards will not go on straight and there will be an incline in them which looks terrible and you will always notice it.

- Long term problems with warping, twisting, straining, cracking and splitting.

- You’ll be on the phone to me immediately during installation as it’s not going together or in about 3 months time when it’s falling apart. I’ll pop out and look at your base and tut a lot, we’ll end up arguing and you won’t even offer me a cup of tea!

What if the base isn’t level?

Sometimes we must use what we’re given. There’s not often a great deal we can do about it. Trying to add a screed to a concrete base to get it level rarely works. It simply falls away as pressure is put on it.

If the base is out, we have to fix it before building the cabin. Either it’s demolished and started again or another solution needs to be found.

When fitting cabins myself, which isn’t often these days, I carry a box of ‘slithers’ of pressure treated timber in my van of various lengths and depths. Using these I could often overcome any deviation by adding them to the foundation beam and ‘chocking’ where necessary.

However, if you are going to chock a cabin up for goodness sake make sure it is supporting the whole length and not just a corner.

Here’s an example:

This is a log cabin ‘gone bad’ I recently visited. It’s a bit of a long story but the customer had some particularly shoddy builders in to build it for them who neither cared nor had a clue what they were doing and this was a substantial and very expensive log cabin.

The above image shows their version of chocking up the corner to make up the deficit in the unlevel base. This piece of plywood doubled up was supporting the corner of a huge 70mm log cabin. Not only had all the logs sagged across a 1m stretch the corner joints were also badly damaged and did not fit as it was still badly out of level. The apex also ripped apart and don’t even get me started on the purlins. But if it had worked – the plywood would have rot within a year and the whole thing would drop and destroy the cabin anyway!

Here’s how it’s best done:

I took the building down for the customer and reassembled it correctly. This is how I chocked the fault in the base. Notice I am using tanalised timber, supporting along its length, and kept properly level.

So, with a trusty box of slithers of tanalised timber, you can tackle most unlevel areas. Just make sure you have several depths available to you.

Please though, use timber that won’t rot in five minutes. Make sure the foundation beam remains supported throughout its length and, importantly, keep the building completely level in both planes regardless.

Footprint

All Tuindeco log cabin measurement goes from one end of the log to the other, so a 3.0m wide log cabin is exactly that, from the outer edge of the log to the outer edge is exactly 3.0m. The base doesn’t specifically need to be to this measurement as all the logs have a crossover connection, this is generally 100mm or less depending on the size of the cabin (please ask us for your particular building).

So, for instance the base actually needed for a 3.00m wide log cabin is:

- Length of log – 3000mm or 3.00m

- Crossover – 100mm

Log – (crossover x2) = 2800mm or 2.80m

In this example we could make our base at exactly 2.80m wide and the log cabin will fit on it exactly. Be careful though, there maybe a wiggle in the shuttering or somebody is not as exact as they could be, there’s no room for error when doing it exactly to the footprint so it might be wise to add a centimeter or two either side just in case.

If possible though, I think it looks far nicer. It also has the advantage that when it rains water does not hit the base and fly up and make your lower wall of your smart, new log cabin all dirty and mucky.

Another good idea when making the base to the size of the footprint is to then add a French Drain. This looks really nice and also absorbs the water, stopping it splashing up and also removes the need for guttering. The other advantage is the loose stones can then cover any of the concrete you don’t want to see. Apologies this isn’t a log cabin but I’m sure you get the gist:

Log Cabin Base Requirement Summary

A base can be pretty much made out of anything and we’ll get onto that in a moment but any base provided for any log cabin has to follow this criteria:

- Consideration should be given to the majority of the weight being placed on the perimeter of the cabin.

- Consideration should be given to the weight of the cabin, a 19mm is obviously considerably different to a 70mm.

- It should be 100% level in every direction.

- Ideally it should be square.

- Ideally to just over the footprint size of the cabin.

What base do I need for a log cabin?

I hope with the above waffle I’ve given you a little idea what we’re ideally looking for in a base for your new and sparkly log cabin. I’m not going to go into how to build a base as I’m not a builder or landscaper, nor would I want to be as it looks like jolly hard work. I will however give you a few examples.

Concrete

You can apply a base of concrete in a number of ways, generally done with simple timber shuttering. The average base will be about 80-100mm deep. Below shows a simple concrete base with timber shutting.

We can also get a little more complicated with a block work supporting wall and then filling with concrete, perhaps reserved for the bigger buildings that needs a little more weight supporting structure around the perimeter.

If you’ve got a large building your landscaper or builder may advise steel reinforcing within the base itself, remember though not to forget the perimeter.

Steel reinforcing within the concrete base.

For advice on mix ratios, strength of concrete etc there’s lots of advice across the net. I advise seeking that information elsewhere.

However, from experience, use a mix of one bucket of portland cement to five buckets of ‘all in 20mm’ ballast gravel and add the water slowly. Don’t make it too wet though, make the fluid workable, mixing until uniform in colour.

As a rule of thumb calculate the volume you require (LxDxB) and add one third.

Creating the base is pretty straight forward. Use timber board as shuttering to guide the edges. Then mark out the area and use a tape or string corner to corner to ensure it is straight.

Level the shuttering with a spirit level and pour your concrete. Keep working it across the surface with a board until it is level with the top of the shuttering boards. Allow three or four days and et voila your base is formed.

Alternatively; ask someone who knows what they’re doing. The above concrete method sounds good in principle but I’ve never managed to get it right and still had a few undulations in it, depressions are fine, hills aren’t so good!

Slabs

This probably doesn’t even need explaining. It is a cost effective and easy to apply feature. Again like concrete follow the base criteria I mentioned. Normally a 70mm layer of dry sand and cement is sufficient, tamped down until level with the slabs then levelled on top of it. A quick method and probably the cheapest and can work for most of the cabins we sell.

This I can get right and is pretty straightforward, just make sure it’s all level.

I have in the past tried the various other ‘eco’ slab bases but I could never really get on with them. They were more expensive than a simple concrete slab and still required the same amount of levelling. I still remain unconvinced of their real benefit, but I hope that opinion changes.

Timber Frame

This is by far my favourite method of laying a base, of course it’s not the best way I just enjoy doing it as there are so many permutations and challenges.

It’s using a timber frame supported by stilts, or pads or simply paving slabs positioned at intervals. I find it a good environmentally friendly solution and great for areas where concrete is just not possible or when there are steep inclines to overcome.

There’s no hard or fast ways of doing it so I’ll simply give you a few examples for ideas:

What I love about a timber frame base is that:

- You can move it around.

- It’s truly a temporary structure which is great in certain circumstances.

- It allows air flow, preventing rot to the timber, even if untreated.

- It’s a cheap solution in inaccessible areas for concrete.

- Cheap overall.

- If subsidence occurs you can simply jack up the area concerned and re-pin.

- A good system when flooding occurs naturally and does not affect it’s environment.

To make leveling the base we do have a nice product. It’s not a bad price either and you can level between 30mm and 140mm using a combination of two units:

Please also see a recent post about a customer’s building for more examples of a timber frame base for log cabins:

Please also see a recent post about a customer’s building for more examples of a timber frame base for log cabins:

Log Cabin Base Construction Summary

I’ve missed out loads of other ways, one of them being a brick or block plinth such as this:

There’s also systems on the market such as this:

There is truly a myriad of systems out there to form a base for your log cabin. Much of it is down simply to cost and then personal preference and of course convenience, more than likely I’ve confused you more but no matter which method you pick:

If you want to be able to install your log cabin easily and then have it last for year and years then the base must be to the following criteria;

- Give consideration that the majority of the weight lays on the perimeter of the cabin.

- Give consideration to the weight of the cabin, a 50mm base is not going to cut it for a a huge 70mm beast of a building.

- It should be 100% level in every direction and this is THE most important factor

- Ideally it should be square.

- Ideally to just over the footprint size of the cabin.

Just one last thing for you to consider and a bit of advice. If you’re opting for a concrete or paving slab base think about adding a damp proof membrane either within it or on top of it. This will then stop any damp coming up and impacting on your log cabin during the winter months.

I hope this has helped Feel free to comment or contact me if i can help further especially with the timber frame bases. I really enjoy these and love seeing them used in tricky situations. Likewise, for advice on the slabs and concrete bases it might be better to ask a builder!

Update

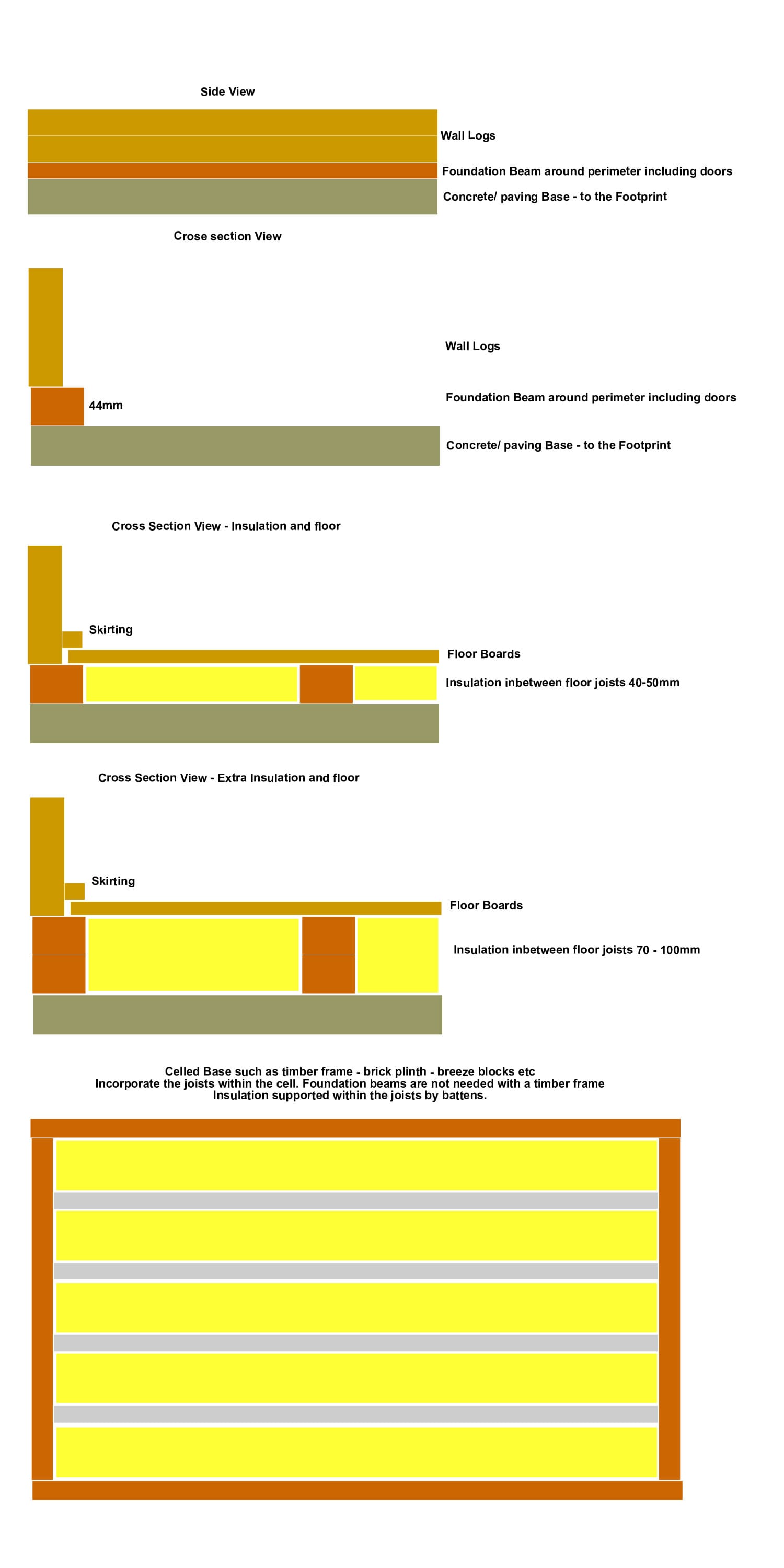

Here’s various diagrams I have since added to other posts that may also benefit the reader of this post:

Advice on using a Damp proof course in your base.

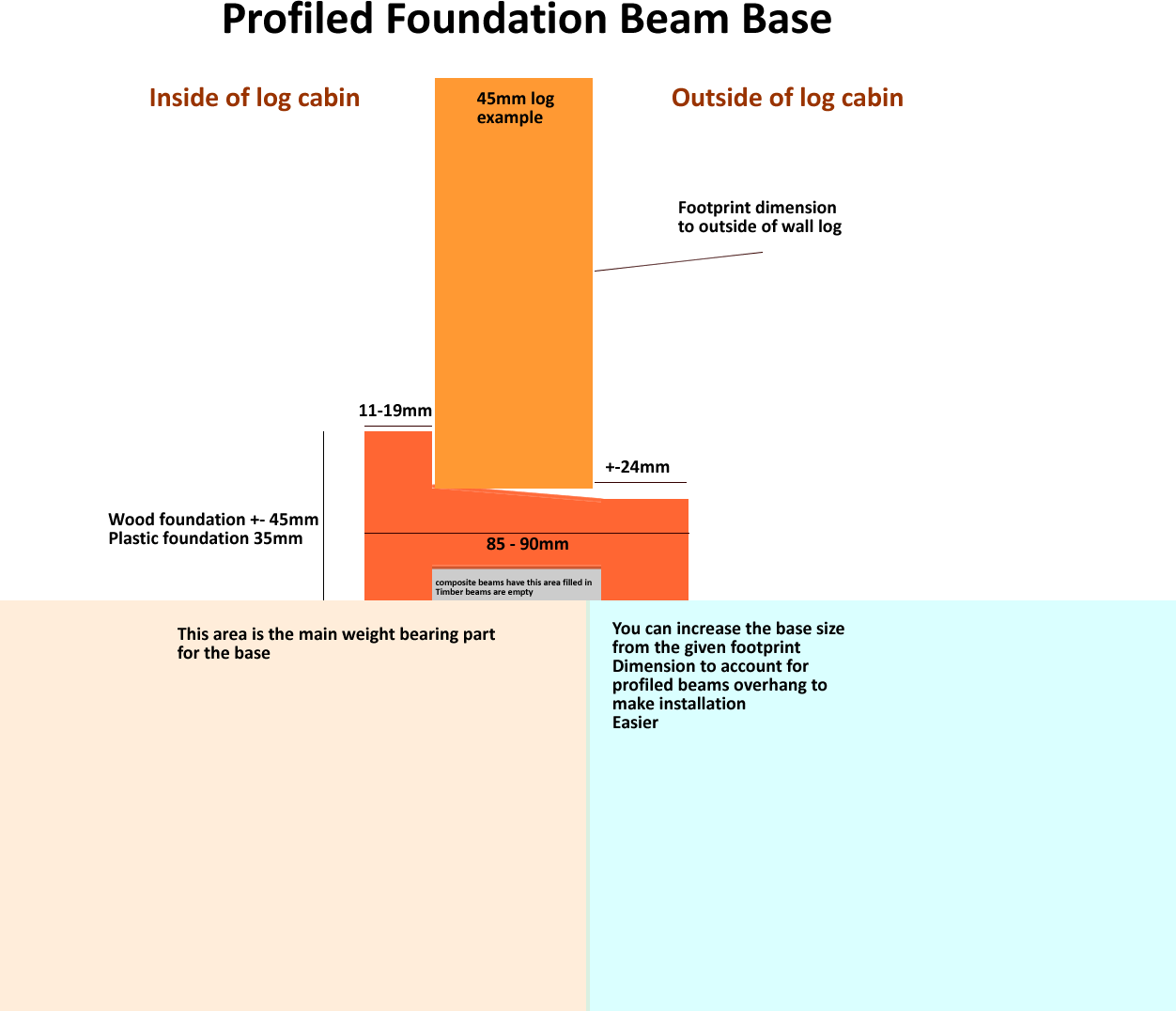

The base configuration when using our profiled foundation beams.

Insulation in the floor and foundation beams.

FAQs

To summarise this post, let’s go through some the most common questions we encounter in relation to your Log Cabin’s Base Requirements:

What are suitable bases for a Log Cabin?

Any base is suitable as long as it is 100% flat and level, it supports the logs throughout their length and is free from subsidence over the cabin’s lifetime.

What foundations do you need for a Log Cabin?

The standard foundation beams we supply are suitable for all our Log Cabins. Optionally, you can choose profiled beams for the added benefit of

How much space do you need around a Log Cabin?

No additional space is needed as our Log Cabins are designed to be built around the perimeter of a base.

If you have enjoyed reading this page then please come and take a look at the log cabins we sell. If nothing else, it will help you understand what designs are possible if you’re not already beyond that.

Perhaps you have some follow up questions, please make use of the contact form below. We will be happy to help.

Hi, Just about to buils a base for the LOTTE CORNER LOG CABIN 4.0X4.0M. I was going to use timber but veru expensive and i could not work out where the corner cut-away was to be placed. I am now thinking of doing a solid concrtete base, can it be over the the 3.8m x 3.8m or does it need to be exact ?? If exact doyou have a floor plan showing the cut-away corner please. Or can it just go on an oversized flay level pad, 4.2m x 4.2m ??

Thanks in advance Howard

Hi Howard

Very happy to help with base sizing for the lotte log cabin

The safest bet will be to make it square, the the minimum base size listed 3.8×3.8m. However what i can do is email you the plans so you can see the corner cut off in more detail.

Hope this helps, Ben

Hi

Is it possible to use the 44mm x 70mm Base Timber and slabs supported every 1.5m or so or is the 44mm x 70mm timber too small and should only be used on a solid concrete base?

I obviously don’t want any sagging

Thanks in advance

Hi Matt

Yeah you have suspected correctly, The 44x70mm foundations are not man enough to be only supported at intervals.you would want a fully supported, flat base

Timber base advice can be found here, but the Hight could be the problem with this

Hi Matt

Yeah you have suspected correctly, The 44x70mm foundations are not man enough to be only supported at intervals.you would want a fully supported, flat base

Timber base advice can be found here, but the Height could be the problem with this

Hi Richard. What would the best base be for a somewhat boggy land? And not entirely level, to boot. Thank you before hand.

Hi Sergio

If getting a truck or so full of concrete isn’t viable for your log cabin, a timber frame base could be your next best option. Digging footings for the supports and infilling with post mix

Hi Sergio

A little tricky to offer the best advice without being on site but you could dig footings for blocks and lay a raised timber frame, Supported with base pads like these perhaps

If the footings are large and regular enough you can help prevent anything sinking

Hi Quick question, using a timber frame, so the foundation beams are not needed correct ? hence I was planning to use battens to support insulation sheets e.g. 50mm fitted in to the timber frame so the flooring can be fitted on top of the timber frame, does this sound OK ?

Yes, that sounds great. The foundation beams are not needed if you’re putting your log cabin onto a timber frame unless you want to use them for aesthetic reasons or to wick away water by using the composite beams.

This seems a great forum. I noticed a few queries reading concreting a base slab. So, a few thoughts from a retired civil engineer… Just my personal opinions, for what they are worth. Don’t take them as gospel, make your own minds up!

Concrete mixing:

Always use good quality graded ballast from a reputable supplier. (Purists are allowed to use the appropriate mix of sharp sand and stone). Cheap, ungraded, ballast and sand are full of dust and fines, which will produce a weak, dusty concrete. Five parts of ballast to one part cement is usually fine, but perhaps four parts to one if the weather is cooler (then it will go off faster) or if you just want a really strong mix. Don’t skimp on time in the mixer – be thorough.

If using ready-mixed concrete, specify the cheapest structural grade – it’ll be quality controlled and much better than some suppliers’ nominal 5:1 mixes, and shouldn’t cost much extra.

Water:

“More is less”. More water will result in a weaker concrete. Use the minimum amount of water consistent with a mix that is just workable and no more. Experiment to find out what amount of water works and measure it so your mix is repeatable. Try working the concrete with a spade or shovel to see how workability increases. When you tip the concrete out of the barrow it should form a mound and only “slump” a little. It should not be runny or in any way self-levelling. Any wetter concrete can be spread in the bottom of the concrete pour where it won’t matter much – you can’t really put it in the dust-bin.

Shrinkage:

Contrary to what some may think, concrete shrinks slightly as it sets. A wetter mix will shrink a little more. For a base slab you don’t really need to worry about allowing for shrinkage as it’s a very small amount. More cement = a little more shrinkage too.

Cracking:

Since our slabs are relatively thin compared with their area (length x width), it pays to think about cracking. Concrete is very strong in compression but very weak in tension. That’s why we reinforce it. Reinforcement helps control cracking, which is important for our “ground bearing” base slabs. Reinforcement can also add to the strength but we don’t need to worry about that aspect as structural loads are low. Cracking will often occur if the ground beneath a thin slab moves slightly, as will happen, for example, seasonally if there is clay in the ground or if there are tree roots near by, or if loads from the building/support from the ground are uneven. (Hopefully you will have used hardcore or MoT Type 1 sub-base, well compacted, which should reduce the problem but may not eliminate it.)

The answer is to put some reinforcing mesh fabric in the slab. This works by causing one or two large cracks to become a large number of microscopic cracks which are self-healing. Lay the concrete to half depth and compact it, then lay your mesh, then lay the rest of the concrete on top. I would use “A142” mesh fabric, which has 6mm diameter bars, for a 100mm thick slab. You could use two layers of A142 (or one layer of A252 – 8mm bars) for 150mm thick. Make sure you have a generous overlap between the sheets of mesh fabric or you will induce a major crack! By the way, A142 mesh is mild steel – it can be cut/trimmed easily with suitable bolt croppers and is readily available.

You won’t need movement joints unless the slab is relatively long and narrow (unlikely for most rectangular bases), in which case an alternative might be to just pop an extra layer of mesh in.

NB If you are doing concrete strips around the edge, then perhaps use a couple of 10mm or 12mm diameter reinforcing bars instead/as well, depending on width of strip. These are ribbed so they grip the concrete. Being a higher strength steel you will need a disc cutter instead of bolt croppers.

Damp proofing:

It’s always a good idea to put a DPM under the slab, but not only for preventing rising damp. A DPM will prevent the wet concrete losing moisture into the ground below and taking cement/fine material with it. Blind the hardcore/Type 1 sub-base with building sand before laying the polythene to avoid any punctures.

Compaction:

Make sure the concrete is well compacted to get rid of voids and air bubbles, and to make sure it surrounds the mesh closely. You can do this with a spade or shovel by “diddling” (?!) vigorously. Do this just enough – not too much or the sand and stones will separate.

Finishing:

Obviously, tamp your concrete using a dead straight board or alloy box section resting on the shuttering. This will bring up the “laitance” to the surface to enable a good finish, and will ensure you have the slab dead level – but only if your shuttering is also dead level and robust. Do not skimp on the shuttering. Once the concrete has stiffened a little, use a steel float (a nice long concreting one) to give you a good finish. Fill any foot step holes as you go. Check with the tamp as you go.

Curing (i.e allowing the concrete to gain its full strength):

Concrete cures by slow chemical reactions between the cement and the water, with strength building up slowly as time passes. Let the concrete dry out and these reactions stop – the result is weak concrete. Remember that the concrete may seem hard after a few days or a week or even two, but to gain its full strength can take three or four weeks – perhaps a bit less if the weather is warm, and a lot more if it is cold. Don’t try concreting in very cold weather as it will take forever to go off and any frost will ruin it.

Once the concrete has stiffened, cover with polythene sheeting. Light decorators’ dust sheeting is ideal. This will hold the moisture in and prevent the concrete drying prematurely by evaporation, especially if weather is sunny or windy. Once the concrete is hardening well you can weight the polythene down. Leave for at least two weeks and preferably longer to ensure the concrete gains its full strength. (NB Concrete strength is often defined as its strength after 28 days curing under standard conditions – not cold conditions, which would take much longer.)

Meanwhile you can bone up on how you are going to do the build. Possibly you could build over the polythene once the concrete appears very hard, but be very cautious about this as it’s impossible to judge concrete strength by looking at it or poking it. It won’t matter much if the polythene gets punctured, but do allow the full curing time before removing it – you’ll be surprised what a difference it makes.

Removing (or “striking”) the shuttering:

Don’t do this too soon as the concrete may appear hard superficially but actually still be relatively weak – bits stuck to the shutters may break away. Wait for at least two weeks, perhaps a little less if the weather is warm both day and night, longer if it’s cold. Ideally put some floor polish or similar on the shuttering to prevent the concrete sticking to it. A good spray with Mr Sheen or one of his many supermarket friends would probably do the trick or maybe Screwfix or a builder’s merchant will sell you a suitable product. Don’t do this until just before concreting as it will soak in and become less effective. NB Don’t get it on the reinforcing mesh, it’ll de-bond it from the concrete and you’ll be back to large cracks!!

Apologies, but I haven’t time to engage in any chat about all this – this post is strictly a one-off. It’s given in good faith but I leave it entirely up to you to decide whether you want to follow it. There are online resources if anyone wants to dig deeper. Anyway, I hope it helps a few people and please do feel free to chat amongst yourselves.

Hi David. This is an excellent write-up, and it will be incredibly helpful for those looking to build a concrete base for their new Tuin cabin – thanks for sharing your experience. I work with a number of civil engineers and they advised me on a previous project. Everything you’ve said reflects their advice to me. Thanks again.

This may be helpful for others who experience the problems I had with an old garage base. My story is that I had a very old concrete block garage that had been built on a concrete base. When I demolished the garage I found to my dismay that the base sloped badly to both sides by almost two inches (50mm).

In effect I had a camber running the entire length of the base that couldn’t be rectified with any self levelling compound.

Instead of breaking up the base and going to the expense of more skips and recasting a new base, I purchased eight 1.8 metre steel reinforced concrete gravel boards.

Using thick slate and mortar under the gravel boards I created a solid concrete perimeter that is now level in all directions.I intend to install a floating floor over a damp proof membrane inside the cabin and will use plastic shims of varying thickness to get the rafters level.

Using pre-cast concrete gravel boards and slate has solved the problem of my terrible existing concrete base and cost less than £100 to do.

I hope this post will assist others who face a similar problem.

I am planning to build a timber base for my Jutka log cabin (due in 4 weeks – yikes!). The groundworks are underway and i have plenty of pictures. I am building 3 frames that will be bolted together to form the L-shape and then will run an additional 6″x2″ timber around the perimeter. Given that it’s a timber base, i understand that I dont need to use a foundation beam. However, what I am unsure of is whether I should screw the first log to the timber base frame. Grateful for any advice – thanks!

Technically you don’t need to fix the first log at all. But, you will find most fitters will as it stabilises the base as you build up keeping it square and stopping it slip when you have minimal logs in place.

Thanks Richard. Will fixing the first log cause issues as the timber expands and contracts through the seasons?

As it is only the one log this will not cause any problems at all.

I plan on building a timber frame base using 4″x2″ spaced approx 400mm apart. Then covering the frame with 18mm OSB sheets. Will this be good enough for

a 3m x 3m Emma cabin with 40mm logs. The ground has a slight incline so my plan is to use some of the adjustable support pads to level it off.

Do i need to double up on the timer around the perimiter or is this over kill?

That sound ok for an Emma, a lot of the strength and support will come from the uprights you use as well.

Hi,

I’m are looking to purchase a 4m x 3m log cabin with delivery in the spring, hoping the weather will be more favourable by then. I’ve started to obtain quotes for a wooden foundation, which I’m happy with especially as the site slopes a bit. The carpenter we normally use has suggested a timber frame, then using the floor joists on top of the frame, on which the log cabin will sit. He will fill the frame with the earth that will be dug out around the area to avoid taking it away. Also, rather than use a DPM he has suggested using breathable roofing membrane. I have found lots of useful advice on this site and would appreciate your comments on what he has suggested.

I don’t think it’s a good idea to fill the frame with earth as this will encourage it to rot. Normally using a timber frame base negates the need to dig out a lot of soil.

Hi this is a great article and very helpful. I can see with the wooden base that a membrane has been added. Is this a DPM or just a permeable we’d membrane?

The membrane you see is weed matting to stop any nasties coming through.

We’re just about to take delivery of our Jami log cabin and are preparing a 3.0 x 4.4m concrete base. We’re making it 100mm thick. Having not done hardly any concreting before, I’d like to know, should we concrete the base in sections to allow for contraction/expansion or is it ok to go for one big slab? We have a DIY book (reader’s digest) that suggests we should build in sections at this size. Also, should we be adding any metal reinforcements? thanks very much

I’m not an expert on concrete but I do think it will need an expansion joint within it, it’s unlikely you will need to add reinforcement.

I am planning on purchasing the Clockhouse cabin and erecting this on a timber frame, double lined 150x47mm timber on the outside with timbers on hangers at 400mm centres inside the frame. This will be raised from the ground by approximately 100mm on concrete blocks. between the joists in the timber framework I’ll install 50mm insulation board and then on top of this floorboards.

Do I need to install a damp proof membrane or damp proof course? If so where should I install this?

I was thinking of stapling a damp proof membrane to the bottom of the frame but this would then block the air flow which I thought may cause further problems. If I lay this on the ground this would then cause puddles to form under my cabin

As you are using a timber frame base you don’t need a DPM, I think I would add something though between the concrete blocks and timber frame. Maybe also under the blocks themselves.

Sorry, just to clarify, by something do you mean a damp proof course between the blocks and timber, and maybe under the blocks themselves to prevent water absorbing up through the blocks into the joists, or a damp proof membrane across the full area of the base under the blocks

Just between the blocks and timber, maybe also between the blocks and ground contact. There will be no need to go across the whole base.

Hi, I am looking to buy the Halvar cabin. We will be using a base of slabs. Do you put the DPM under the slabs when you lay them and then under the foundation beams and under the flooring planks?! Thanks

If you have a DPM within the base that is generally enough. If the finish on the base is rough using a damp proof course around the perimeter helps to create a seal between the rough base and foundation beam as it is thicker plastic.

We have had a 240×780 cm (44m) log cabin and concrete base recently installed by a dealer. The concrete base has holes arounf the outer perimeter. The timber base is 22mm over the concrete base in the back right hand corner. The concrete base is +-10mm out of level. The right hand walls of the building are not plumb and we are experiencing bowing, splits and gaps in the rear wall panels. The front left hand corner wall logs are also moving upwards leaving gaps bewteen the wall logs. We strongly believe that the purlins and roof beams have also been cut. Please can you advise.

All the weight of a cabin structure sits on the perimeter so it is important the base particularly on the outside is good and strong. Ideally all of the width of the log / foundation beam should be supported, having parts of it overhanging is not desirable.

If a base is not level or the building has not been levelled with the use of shims then you can start to get some odd movement and possible bows in the walls of the log cabin.

If you are seeing gaps appear check that none of the logs are being held and that there is still some clearance above the window and door frame.

It’s not usually necessary to cut purlins other that to adjust the notch where it sits in the logs or planed slightly to finish at the roof line nicely.

Would tiles ( I have some big bathroom floor tiles which I could cut into strips) make good shims? I’m not sure how or if I could get hold of treated wood shims to correct the slope in my existing concrete base….

I haven’t tried tiles, they may work. Or you could source some timber or use the pallet timber, cut as required and give them a coat of treatment.

Thank you. Do you know the acceptable tolerances with reference to the building squareness over base and vertical wall structure or any references? Many thanks

It does depend on the size of building as to what you can get away with, for most buildings though it is not too hard to level with shims, slats of wood etc. I prefer to have the foundations as level as possible, to help this the base or at least the perimeter the beams sit on needs to be level to avoid the use of shims.

You want the base really level and square otherwise problems will ensue. If not vertical, doors will not close properly and will swing open or shut. My timber sub frame is square I guess to within 3mm or so, level wise probably about the same – it took me some time to get it perfectly level and square but it pays dividends.

I have an existing concrete shed base (W 3m x D 3.6 M x 150 mm Height) which I want to extend to accommodate a W 5mx D 3m log cabin. To extend by that amount would require quite a lot of concrete (and it’s at the end of the garden which makes it more difficult to get premixed concrete), What would be best way to do this given the 150mm height? Would it be better to build a series of brick pillars to support the foundation beams (using the adjustable base pads)?

Do the foundation beams sit directly on to the adjustable base pads?

The foundation would not sit on the pads. You would be better to make a timber frame at that point if the base, support that with pads / timber posts / bricks and build the cabin on that an the existing base. You could consider a full timber frame covering all the existing base and the extension.

Thanks for the advice. I’ve ordered some 70mm beams and the pads to construct a frame to extend the existing base (it would be over 2.5m otherwise). What’s the best way to make the joint at the corners (I’m not doubling up the beams)? Do the pads go right under the joined corners?

Thanks

Matt

We normally screw or for more strength we use threaded coach bolts. You may want to use two pads on each piece as they join at the corner, one maybe enough depending on the timber thickness, joint and stength.

I used 4″ x 2″ to create the subframe, doubled up around the perimeter to create 4″ x 4″ and used coach bolt type screws at the corners to screw them all together. If not doubling up, consider a piece of timber on the inside corner so you have some additional strength there. Don’t forget that with log cabin construction, all the weight of the cabin is on the perimeter, you want this to be sturdy!

Hi there,

Regarding base/foundations I am unsure on a couple of points.

1. On the advice of using a dpc / dpm under a foundation beam no matter what. If I am using a composite beam (which presumably is some sort of plastic material) surely that means no moisture can rise up. I am shortly to take delivery of a Sadie 3m x 5m and have a perfectly level concrete base ready for it. If anything the base is a slightly bigger footprint so I will take on board the advice on a silicone/mortar bead.

2. I may have missed this but how close to the perimeter should the first joist be laid?

Sorry if these seem mundane questions but I am not a builder just a very (I hope) competent DIY’er.

Can someone advise on both points please?

If you are using the plastic foundation beams it is still a good idea to use a DPC, this is because it compresses and helps to seal between the base and foundation.

I have ordered a Palma 4m by 4m Cabin, and intend to build a timber frame base for this to sit on. I am considering supporting the structure on paving slabs throughout with each corner on a timber post comprised of 2x 3 by 6 screwed together. On top of these I am using 2x 2 by 4 laminated together around the perimeter, and then I have some of the Plastic Variable height gizmos to support in between these posts at between 80cm and 100cm intervals. I am also using 2 by 4’s to support the floating floor I have ordered, and these are spaced at 40cm intervals with Noggins for stability, again all supported by the variable height gizmos. Firstly does that description sound reasonable. Secondly, when it comes to a Damp Proof Membrane, do I put this directly on top of my timber frame, with the floating floor sitting on top of this alongside the first layer of the cabin walls? Lastly, if I decide to go with floor insulation in the above case, I presume they would sit between the timber frame beams below the damp proof membrane? Does that sound like a good plan? If not how would you improve the above?

Your base plan sounds good. Remember to make the base to the footprint of the build and not the overall dimension. The cabin and floor will sit directly on top of the timber base. Insulation will go in your base supported how you see fit. The DPM can go under or on top of the timber frame base.

I’ve just had a concrete base installed for the Annabel cabin (5m x 4m base) – the base has been shuttered and appears at first glance to be completely level which is good. My only concern at the moment is that the finish isn’t completely smooth and there are some ripples/dents/bumps in the surface. Is this likely to cause me problems or should it be ok so long as the base is level? Thanks

If the concrete is uneven you may not be able to accomplish a seal between the foundation beam and the base which may let water in depending on your base. If this is only minimal or rough then usually the use of the damp proof course and timber foundation beams will create a seal. If it is worse you can consider the use of silicone sealants, expanding foams, fillers or in extreme cases a fillet of cement.

Ok thanks, I need to check it over properly but it did look a little concerning and I’m not sure i’ll definitely be able to get a seal all the way round so appreciate the suggestions. Presumably if the worst of the bumps are in the middle of the base then this is less of an issue so long as perimeter is good?

It i only the perimeter that is the most consideration, in the past if there is only a few larger ones i’ve found a cold and lump hammer works well. Also only use the soft wood foundation beams which also compress into a DPC to create a seal. If it is not smooth the composite foundations don’t give enough for very rough surfaces.

OK thanks – the damp proof course is within the concrete base and unfortunately I am taking delivery of the cabin tomorrow with composite foundations rather than softwood. I’ve got a week or two before I plan on building the cabin, so I will lay the composite foundation beams out on the base once I have them and see how bad it seems. I haven’t paid the contractor yet who laid the base, so I can always try to get them back to rectify if it does look bad (although not sure how easy this is now the base is set). I’m hoping it isn’t too bad and I can find an easy solution!

That’s great it’s in the base. I think I would also put a DPC under the foundations as well to help seal it. It is also possible to hire / buy a concrete planer which maybe something your contractor can help with.

Final, possibly stupid, question – if i put a DPC under the foundations as well as you suggest, to help form a better seal – presumably (since i have a DPM in the base itself) I only need it under the foundation beams themselves, and not across the entire base (and therefore a DPC of 150mm width would suffice)?

Yes, only under the foundations, you will be using the Damp Proof Course as it is thick, the one usually used in bricks.

Thanks for advice on base construction with DPC etc

I have another question about wood preservative prior to Sadolin paint finish

Is it advisable to apply preservatives to both inner and outer surfaces and would you also apply said product to internal track on window frames before sliding them into place.

I will have time before assembly to treat wood with preservatives in my garage. Any thoughts on this would be appreciated.

Thanks Mike

Certainly the very best thing you can do is treat all the parts before you install, including the window frames. This is a real belt and brace approach. But, always make sure you follow the treatment manufacturers advice as regards number of coats. Be aware though as the coats build up it may make installation harder at the corner joints and require more hitting. If I was doing it I think I would treat with the first couple of coats and then build and apply the final two top coats once built.

Thanks Richard

Another question has been come up

The people we would like to install our shed base are intending to use a base of MOT type 1, whacked down and a sand and cement screed upon which slabswill be laid.

The slabs are 32 ml thick and around 60 will be laid for the armund summerhouse

Will this thickness be sufficient to take weight of building

Thanks again

Mike

The base sounds ok but make sure the groundsman is aware of the weight of the building and of course also the load that will be within the building. They will be able to advise on the correct base considering the loads and ground condition.

Hi Richard

Intend to erect Armund corner summerhouse on 3.5 x 3.5 slabbed base.

Base will be wider all round than cabin.

If I use DPC below composite foundation do I need any other sealing addition to stop any water ingress to structure.

Thanks

Mike

If your base is flat and smooth, with the DPC and foundation you shouldn’t need anything else. If it’s dimpled or rough you may need to consider further sealing the join.

I’m installing a cabin on a concrete base the exact size of the footprint of the cabin. The base is approx 5cm – 10cm above ground level and will have pea shingle (or similar) around the concrete base. However, the base does not have a DPM under it.

I will be using the cabin as an office and will be spending a lot of time in there, so want to make sure I do a thorough job regarding damp proofing!

I plan to put DPC around the perimeter foundation beams, as per your diagrams. I then plan to lay DPM inside, overlapping the DPC. Then lay the floor joists on top of the DPM, lay the insulation, staple the DPM to the perimeter beams (I think this is what you mean by ‘dish’ fixing?), then trim off any excess DPM before laying the floor boards. I’ll also run silicone on the outside of the cabin around the perimeter, where the foundation beam sits on the DPC.

2 questions I hope you can provide some advice on:

1. Where the DPC will lay flat on the concrete base, with the DPM overlapping on top of it, should I use jointing tape to create a seal between the DPC and the DPM? Or is there another way to create a seal? Or will the overlap be enough?

2. I plan to buy a wide roll of DPC. On the outside of the cabin, should the DPC fold down at the edge of the concrete base into the pea shingle, so if any water runs down the walls of the cabin, it hits the DPC at the base and runs off it into the shingle?

I’ve found this page really helpful, thanks for putting it together!

It is not normally necessary to seal the DPC and DPM, the overlap should be sufficient.

You could fold the DPC down the front for an extra belt and braces approach, I think I would then face it with treated timber for aesthetic reasons.

Hi

I’m planning to buy a Torsten and want to insulate the floor using something like celotex. I’m thinking of using paving slabs and maybe timber frame adjustable base pads. When you install the floor insulation, what does it sit on? Do I need to flag the whole floor area and do I need to add a DPC on top of the flags?

thanks

If you have a base of paving slabs or concrete then the insulation would sit on top of it between the floor joists. If you are using a timber frame base then you would support the insulation with slats or similar.

Hi Richard. Thank you for all the great information you blog. I am about to order the Lory cabin and I have a builder ready to assist. I live in NW Scotland on the coast of Argyll. So my query relates to the base. Its’ quite rainy here now and then but I would really prefer not to use a concrete base for all the reasons you cite. I am given advice my friends nearby that in this part of the world a concrete base is a must…are they correct? And if not a concrete base then please can you advise the best option. Its a flat very sheltered site at the rear of the house and tucked into a corner between hedges. Thank you. Lynn

I think your best option would be a timber frame base as per the examples above. It is cost effective and very stable.

I built a timber base and have not looked back, largely based on the advise and comments here. Can see some photos here https://community.screwfix.com/threads/die-lorelei-2017.187656/

Timber is best for sure, but on a solid foundation. The 6″ legs I used seem up to the job and with plenty of support within the base too. Make sure you use a DPC so moisture is kept out as far as possible.

Hi im after some advice I plan on sitting my timber base on slabs. Will it be ok for me to sit them on sand or gravel or will it need to be a sand and cement mix the slabs are going to be slightly sunk into the ground . Thanks

I’m no landscaper so other people may have better advice but normally you would place the slabs on a bed of sand. A mixture of sand and cement will give very stable support.

I am planning to buy a Karen log cabin when I move into my new bungalow. All this advice and finding Tuin has made the project exciting!

One topic I have not seen covered is the way a high base which projects above ground can take your cabin over the 2.5m at ridge. Already I am concerned that 50mm insulation on top of the roof will make it too high! Comments welcome.

I am 66 and have a bad back, so I considered a ground screw / timber beam solution – nice and light, but with 150mm beams, much too high.

I shall probably go for a plastic grid base and found Probase, which supports 16 bull elephants and requires no gravel infill! Ground will need reducing and levelling but they say it needs no scalpings below. Being empty plastic, it needs no DPM on top, only beneath for weed control and will breathe better than concrete or slabs. My 50mm Celuform floor will sit straight on without floor joists.

And the cost is low, £250- £350 for a 5m x 3.2m Karen.

Any comments welcome, as I have not made a decision, but my concerns are low weight, low height, and ventilation.

Even with the probase I would still recommend you install a DPM to be sure as dampy can still come up through the cells of the base tiles. You can also insulate within the roof rather than on top if the height is a consideration although this is a little trickier and ventilation needs to be allowed for within the roof.

Thank you for your very informative site, it has really helped me in making the right decisions. I, like you, are a timber man, and really enjoy the design and creation of these, also, i dont know why, but I just feel that wood is the way to go.

I have drawn up my plans using your posts and probably done far too much research online 🙂 and I am confident on the construction and stability, so thanks for all your time putting these together.

The only question i really have is, If this is a Timber frame, do i still need to use the foundation beam or not? Is the foundation beam used for under the door or does the door framing include this? i thought i read somewhere in your posts that if it was a timber frame the foundation beam was optional but i cannot seem to find it again.

Thanks again

Adam

If you are using a timber frame base you do not really need to use the foundation beams as you are already lifting the building away from ground contact. You could though use the composite profiled beams which give it a nice finish and also a natural lip around the base.

Foundation beams go around the entire building including any door way.

Hi Richard, we are about to order the Hendrick 5by5 cabin and I’ve been looking at a interlocking plastic base system. Not getting any younger I was looking at something easier to install but not losing the strength that other more established methods bring. The foundation work promises to be the more back breaking work so was wondering what your thoughts were in this method as some other cabin websites offer this system or suggest it but not found anything mentioning 14ft by 14ft anywhere and how that might stand up to this size cabin. Thanks for any guidance you might offer…

As with any base system the strength, integrity and longevity is going to come from what is under it. As you mentioned; the most back breaking part will be the preparation according to the ground conditions and the structure you are installing.

Remember though all we are interested in with a log cabin is that you support the perimeter of the building so it is 100% level and free from subsidence over it’s life time. How the floating floor part of the build is supported would depend on your requirements and imposed load. For larger buildings it is often more economical to provide a strip foundation around the base and then pier foundations supporting the floor joists. Of course toy will always provide a damp proof membrane within or on top of the base you use.

Regarding the plastic base interlocking grid system; I have used these but mainly with greenhouses as the drainage they offer is perfect for a greenhouse. For sheds, summerhouses and log cabins or indeed any other building I’m still not convinced and personally do not really like them. My top reasons being the cost, a paving slab is around £2.50 – £2.80. The plastic ones are around £5 – £6.00? That can potentially add quite a bit to a base. I’m also concerned how a seal is formed between a log cabin foundation beam and also the effectiveness of a damp proof membrane considering you would have to use it either under or on top of stone shingle that could present a risk of puncturing the membrane maybe.

With that said I can see a huge benefit in the weight reduction in using them and transporting them to site and also maybe laying them. But, the groundwork still has to be done so large quantities of aggregate still needs to be taken to site so if you’re taking that why not take the paving slabs as well.

Or you could also use a timber frame base if the distance, bulk, weight and cost is excessive.

I can see certain times a plastic interlocking grid would work but personally I still favour the three main methods for economy and ease with a log cabin.

Thanks for this. Different people I’ve spoken to say the same. If your going to do it then use a concrete foundation. I will just have to take my time and get the base done properly and place the order for the cabin to arrive at the right time. Great advice on all the blogs on your site. Thanks. Will check out Martins ground screws suggestion as well.

I installed a Tuin 5×3 m cabin last year on these innovative steel ground screws as foundation posts and a timber frame as base. They were so easy to install and no digging at all. They are really good alternative to concrete or wooden posts. https://www.groundscrewcentre.co.uk

Thank you for these details, this is not something I have ever used. I will have to investigate these myself.

I want to lay a concrete base to the exact size of my log cabin garage. What considerations need to be made for the expansion/contraction of the building? Is it simply a case of measuring the footprint or is there anything else to consider?

Thanks

Ideally the base will be made to the exact footprint of the log cabin. There is no need to account for expansion of the logs lengthwise as this barely happens, expansion and contraction only takes place across the width of the log.

Great informative page. I am from a construction background but its still good to see detail like this for a specific project such as a log cabin and the pros, cons, do’s & don’ts.

Now to order the materials :-).

Many Thanks.

I’ve used the information on this site to design and build my log cabin sub-frame, out of 4×2, and its an excellent base, much better than concrete. So thanks very much for the information here, its been invaluable. I’m in contact with others who are doing a similar job but have a concrete base and its causing all sorts of issues as water can get in and has nowhere to go.

We are expecting our Hendrick cabin any day now. I’m bulding a raised timber base, and I am about to install the floor joists. One thing thats puzzling me is that I often see photos of the joist hanger height straps folded over the top of the perimeter frame … this plus the height of the nail heads is surely going to mess up the nice flat surface. How do people get the first log to sit properly on top of this?

Thank you for all the advice on this site, it’s been really helpful.

Joist hanger straps are only generally only 1 – 2mm thick and can easily be knocked down flush with the timber frame base. It should not be a problem getting the bottom log sitting nice and flat.

Hi Richard, This is a great and informative blog you’ve put together. I’ve got two cabins in my garden I’ve put in over ten years ago. Both are sitting on concrete foundations and are still doing fine. The only thing I’d say about the base work was the time and destruction to my garden to put them in as well as the delay in building the cabins themselves waiting for the concrete to set. I’ve started installing ground screws for Stop digging which are perfect for log cabins and garden offices. Just last week I put in 20 screws for a 4×5 meter garden office and was in and out before lunch at a property with no side access. No mess, no excavating or soil to take away, square and level ready to take the timber. Oh and no concrete. I thought it might be an option worth mentioning. Best wishes, Gil

I have seen the ground screws online but as yet I don’t know of any customers that have used them, I have no experience of them. I’d be interested in seeing them in action though and views from anyone that has used them. I do wonder what benefits have they over a timber stilt supporting a timber frame though as the cost is going to be quite a bit higher I think?

Richard, I have ordered an Aiste cabin from Tuin and as my garden has restricted access and an terraced I opted for 12 ground screws to support a laminated timber framework base. I was wondering if 47mm by 100mm timber would be adequate as the price difference for 47×150 is not an inconsiderate bump up in price.

Any size timber can be used but this of course depends on the support you give it, if you are using smaller timber then more support is needed, you can also consider laminating it for strength. Consideration should be given to the imposed load – the things you are putting in the cabin, sometimes this can weigh more than the cabin itself, especially in the case of a home gym.

Where the perimeter isn’t level you can cut strips of bitumen coated roofing felt to support the walls. It won’t rot or crack and the profile changes when weight is applied just enough to fill the void.

Not a bad idea, we tend to do this under floor joists that are bouncy in places.

Hi Richard, I have a 2.0×2.9m Tuin log cabin coming next week which will sit on a concrete slab. The old slab was extended to accommodate the footprint of the new log cabin. Unfortunately, the extended slab on two edges isn’t level – there are some low bits and some high bits with the variation being within the range of about +-10mm. I’ve read your blog and know that I need to get some tanalised timber ‘slithers’ to shim the foundations. Do you know where I can source these in the UK? I’ve been looking at marine ply sheet as an option but am not sure if it is sufficiently rot resistant. Finally, is it possible to plane away material from the foundation beams without compromising the pressure treatment? Thanks.

As well as timber you can also consider plastic packers if the runs are not too long. If you use timber as a packer it is a good idea to treat these with a good wood treatment, i would not use marine ply as a shim. You can plane the foundation beams but this will compromise the pressure treatment but with a good treatment such as black tar or similar when in ground contact it should be fine

Hi Richard, have you come across the Krinner ground screw system and their use with wooden cabins? They look like a great alternative to wooden post on a timber frame base, on the face of it cheaper and quicker than a concrete equivalent. They offer a company install or self install with a two week option rental of their equipment.

I haven’t come across those before, they look similar to the spirafix system which I have used in the past with some success. If you use them i’d love to know how you get on.

Hi Richard, great advice on this site. So we’re going to buy one from you this week! I have already built a timber frame for a deck at 400mm centres using 6×2 all supported by 4″ sq timbers in concrete every other joist and riser support every joist. Overall size 6×5 mtrs. The idea was to put the 5×3 summer house on it, then deck round it. The summer house beams would be across the joists so a nice even spread of the weight. So my question is this. Being 400mm centres the joists are not going to be exactly under the perimeter but will be close. Is this going to be an issue? Thanks again for a great site.

The logs will need to be supported along their length around the perimeter dimensions. It maybe better to deck the entire platform and then build the cabin onto it.

Yes, I think that makes more sense. Also solves an issue about the floor as I want to insulate so would need to add a false lower floor otherwise to support the insulation. How high is the door above the base level? In other words how much height do I have for the floor?

When we supply a floor the joists are 44mm thick, you have enough room to then add either 18mm or 27mm or anywhere in between on top.

Thanks. Last question… honest! How much gap should I leave around the floating floor for expansion/contraction. 5mm? Thanks again.

At this time of year – Spring / Summer I would be looking at a 5mm – 10mm gap. During the Autumn / Winter months this would be slightly less due to the moisture content in the timber caused by relative humidity.

Ive ordered a small log cabin from a local supplier today. 3×3.3m. I assumed it would be built on a frame of tantalised bearers. I was told that the underneath of the whole floor is tantalised…not the rest of the cabin..and as it will be sitting on my timber decking with no bearers I wondered if this isn’t a good idea? I have asked for the damproof membrane to be laid on top of the decking and this is being done but I’m still worried about possible damp and rot. I’m female, no clue about anything to do with construction but have been reading up and looking at cabins for a while and I know that bearers on a concrete base is usually the norm. The cabin must go on the deck there is nowhere else for it to go but can you tell me if I should be insisting on bearers?

Most cabins are untreated and depending on your supplier are made from Spruce or Pine. Spruce is the better material if you can get this. Ideally we like to protect the first log of the cabin from ground contact and we can do this with a foundation beam, a damp proof course, a timber frame or even a brick course.

If you are placing a cabin on decking then generally you are taking the first log away from ground contact. I would though always recommend a damp proof membrane between it and the floor. I would also like to see some protection against the fist log. If you have it directly onto decking you could also consider a fillet of silicone against the decking and the first log to stop anything getting underneath, alternatively a damp proof course under the fist log will also help.

Another good idea is to treat underneath the first log and its sides. A good quality treatment is always recommended, with enough layers for a good level of protection.

I have a question regarding the untreated logs used by Tuin. Have just installed a Tuin Mitch, in the description it say the product is ‘immersion treated in green’. Is this a preservative or do I still need a treatment for the exterior?

The immersion treatment is a anti rot preservative. It does not though waterproof the logs and you may like to consider adding a further treatment to accomplish this.

I have a concrete base of 22 ft by 13ft which previously had 2 small sheds on it when i moved it, after pulling down the 2 small sheds i would like a 20 x 12 / 6 x 4 summer house on the base place. the problem is there is about a 6 inch incline on the 13ft depth part rising from the bottom to the top. the width of 20ft is level. can i lay a timber base on top of the concrete? or would chocking be an option. any help much appreciated.

That is quite a drop, it maybe an idea to consider chocking this level. you can place a timber frame on top though and use this to create the level foundation

Hi – this is a really useful article. What are your views on the plastic rapid fit type foundation grids? These were offered to me by the log cabin retailer as a very quick and cheap alternative to a concrete base and also claim to offer very good drainage, Do you endorse their use?

Thanks

i have seen and used the rapid pads / eco base / plastic tiles before but I’m still not convinced. You still need to carry out the same preparation when using them as in levelling and laying sand as you would when using paving slabs. Plain paving slabs are cheap whereas the plastic ones are quite a bit more expensive. The only benefit I can see from the plastic slabs is that they are light and easy to work with. They are though great for use in a greenhouse as they provide drainage.

in Holland we here a lot about screw fundations. It’s rather expensive though But if there is a leveled pavement and a wooden fundation is that good enough?

The best base for a log cabin is 100% level, square and free from subsidence over the lifetime of the building. a timber frame or paving slabs, concrete etc can accomplish this very well.

Trying ro read everything to educate myself in preparation for building a cabin on our property. We are tearing down a 117 yr old homestead. The new cabin will require a foundation. Your article has made the most sense to my dense brain and I am beginning to see the light. Thank you for writing it and being so concise and clear. I am saving this.

Bonnie

Feel very confident after the thorough and well written information provided thanks

Fantastic advice and insights here – thank you!

I’ve just had a concrete base poured and will be building a 44 or 70mm wall cabin on this in the summer.

The base measures 2.7 x 5.2m, and I plan on building a 2.5 x 5.0 cabin. The base is generally dead level in the short direction, but the long direction has a slight ‘hump’ at about 3m. I estimate the level from the hump falls away by ~10mm by the time it reaches the ends.

I know that the base needs to be level, but just how level? Will the cabin foundation need shimming to account for this, or would there be enough flex in the cabin to conform without causing structural issues?

Thanks

The base should be as level as it possibly can be, having a hump will cause you a problem, please do not rely on the logs to flex and accommodate this. The options you have is either to shim the foundation beam (if you are using them) or alternatively cut away the foundation to account for it.

Since my last post I have gone ahead and had a reinforced concrete base made for the shed. As this was on a sloping garden the base has to be slightly in the ground at one end and higher at the other, which has also meant building a retaining wall! More than half of the cost of the shed again and I think I got off lightly.

Kind Regards

Christine

Fantastic, thanks for your reply. I’ll work along the lines you suggest.

I am currently planning a 20ft x 14ft 44mm log cabin in my garden. The garden is quite bumpy and slopes in both directions. I was planning on levelling the area and having a concrete base, but the soil is clay so this will have to be quite deep I think to prevent the concrete from cracking. Any ideas to minimise the expense would be very gratefully received.

The easiest and cheapest method is to use a timber frame. Please see this post: Timber Frame Bases

What is not clear to me, and I have not seen discussed is the means of bolting down the composite base beam to the foundation, be it concrete, or raised timber frame on posts.

This would seem important in the very high winds during winter months.

Thanks, Steve.

It is a good idea to fix the foundation to the base in cases of buildings in exposed areas. This is also applicable with garages or open cabins to give additional support either side of the entrance. Fixing of the foundation beam can be accomplished with a number of methods as required including rawl plugs and screws, L brackets or compression bolts.

Great post, thanks!

could the steel reinforced concrete base be just O shaped? (i.e. going around the main supporting perimeter)

I’m planning a 6mx4m cabin and would like to limit the amount of concrete used

For larger buildings and to save money it is a good idea to concentrate only on the footprint of the walls of the log cabin. This is the most important thing to worry about and which effects the main building. The floor could be supported with piers at intervals so you don’t have to have a huge slab of concrete.

The comprehensive advice you give is extremely helpful, thanks. My query is: – I am planning to have a Rune which is 5m x5m. In your above advice, you say that when making the concrete base, concentrate on the outer perimeter, as this is where most of the weight of the building is supported. You say that the concrete base doesn’t have to be a big block, you can make a surrounding base with the floors supported by piers. Could you explain this in more detail please?

a log cabin and the floor need to be treated as two seperate things. For the cabin it must be supported at the footprint of the building and the support need to be 100% level, square and free from subsidence. Therefore for larger cabins, for budget sake, you could consider making a ‘footing’ which carries out this job. The could be a strip of concrete, brick course etc.

For the floor you could consider using paving slabs, cast concrete at intervals to support the floor joists. This would be similar in principle to the timber framed bases.

Making strip footings and then using piers to support joists can make the base considerably cheaper.

I’m not clear whether concrete base should be square-shaped even for a rectangular building or not! Also, should I use the points where the wall boards intersect to determine the size of the base or the full length and width of cabin? Anyway, brilliant blog and thank you for the valuable content.

The base needs to be the minimum of the footprint of the building. This post helps to explain the ‘footprint‘ This does not take into account of the corner cross overs which are not critical to support, it also looks better in my opinion.

Brilliant advice thank you for taking the time and your honest and heartfelt advice.

My concrete base does not have e dpm. I am erecting a 3 x3 cabin in February. Shall I just lay a dpm on top of concrete same size as cabin and build on top? I’m worried it may get damaged during build in floor area by stepladders. What do you advise?

Suzanne

If you cannot put a DPM within the base then as you have said putting it on top is best. Of course as you have said this will get damaged while you are installing, it is also very slippery and dangerous. Personally I will use a roll of DPC around the perimeter of the cabin between the base and foundation. Then build the cabin and finish the roof. Then lay out a DPM inside the building and dish it against the foundation beams. Then lay the floor.

Thank you. I have found the advice and instructions on this site incredibly helpful. It has given us the courage to attempt a self build of a pentagon cabin.

Regards

Suzanne

I erected a Tuin 5m x 5m on a steep dirt slope in Greece.

The whole thing sits on joists 200×50 forming a timber suspended floor at 40cm centres with noggins at 600mm centres. Whilst half is supported on a cast concrete wall on a concrete base the other half is sat mainly on 2m tall 60cm x 60cm concrete columns.The columns contain reinforcing bar sunk well into the soft ground and are sat on 120cm x120cm x 45cm deep concrete pads.Large pads on soft ground are must. Intermittent timber supports sat on concrete pads front and sides were also necessary.

fantastic explanation

Really helpful advice as i have just build a concrete base out of concrete blocks to hold the weight of a 5.0m x 4.0m log cabin, most helpful thanks

Such a good article. I’m building a log cabin in Spain, on quite steep mountain-ey terrain. Was wonderin whether a timber base could be used on stilts of different lengths, then a cabin just built on top. From what I understand, this is possible!

Feel free to e-mail me, I’m willing to take all the advice I can get 🙂

Now to check out the rest of this site.

Once again, great article.

Good article. Helpful comments with a large dollop of common sense!

Good informative piece…

Well written common sense. Cheers.