Log Cabin Roof Strength – Sometimes we find ourselves at a bit of a disadvantage selling log cabins in the UK. The main reason being, standards, we have them but don’t really need them here!

UK Standards in Log Cabins

In the UK there are no building regulations for garden buildings, there’s not even guidance. The UK can make anything they want and shed manufacturers do. Same with garden summerhouses, greenhouses and of course the same with log cabins. Especially when they are ‘Made in England’ or for the UK market and designed for it’s crazy planning regulations.

Basically a manufacturer can produce anything they want to, and they do.

Europe Standards for Log Cabins

The trouble we have when competing in the UK is Tuindeco sell across Europe.

To do this they have to meet certain standards and not just make ‘anything’ they feel to a price point.

For instance:

- Germany, it is required by law, that there has to be a snow loading capability of 120 kg/m.sq,

- Austria and Switzerland it has to be 90 kg/m.sq.

- Spain and Greece are substantially lower of course. However there are still standards, a lot more so now the Euro-Codes are being adopted more and more.

Costs of a good Log Cabin Roof

Trouble is, when selling in the UK we then have the costs of this strength when compared to UK companies manufacturing whatever they fancy with no regulations or standards to follow. This can sometimes see our prices being slightly higher on some buildings. It can also raise a complaint such as this which I saw mentioned in one of our reviews on our site:

“I would happily foregone the extra 9 cm in height that would have reduced the cabin apex 2.5m height and therefore ‘legal’ as regards planning aspects especially within boundaries to borders of less than two metres.”

And this is part of the problem we have, you’ll look at the price, the height, but have you thought of the strength you are getting? Will it last over the years without a sag developing?

A sagging roof can develop over time due to a miscalculation of loadings or cheap manufacture.

Weight applied to a Log Cabin Roof

Lets, for a moment, pretend we do have standards to meet in the UK. Lets look at a building and what we are designing to:

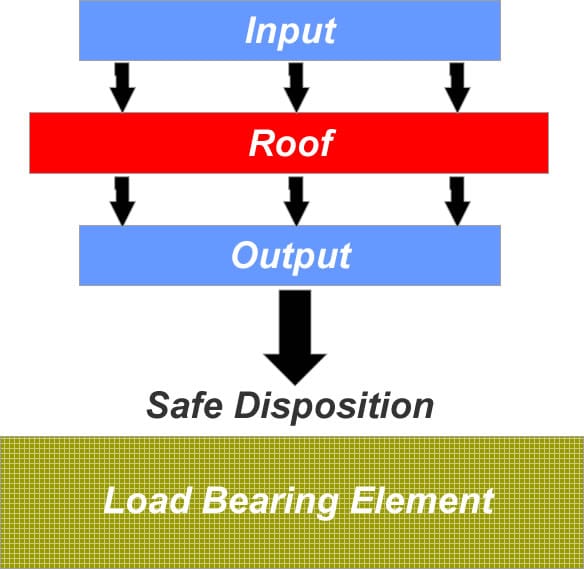

Forces acting on a roof of a log cabin are the same as any other structure – Dead Loads and Live Loads.

The input loads will be made up of the following:

- Dead Loads. This is the loading of the weight of the roof itself. The roof boards, purlins / rafters and what the roof is designed for Including the final roof covering such as felt or shingles, tiles, sedums etc.

- Live Loads. This is the weight applied to the roof from external factors such as snow, rain, wind loading and of course maintenance.

The Output of these loads needs to be transferred to the supporting rafters and purlins, wall logs and ultimately to the load bearing element. We have to make sure the structure is capable of carrying and transferring these forces safely and securely. Of course we also have to make sure that the building will carry on doing this for years and years.

The roof needs to be designed correctly for the loads placed upon it. This will be reflected in the ridge height, strength and number of purlins and thickness of the roof boards.

Snow Loadings in Log Cabins

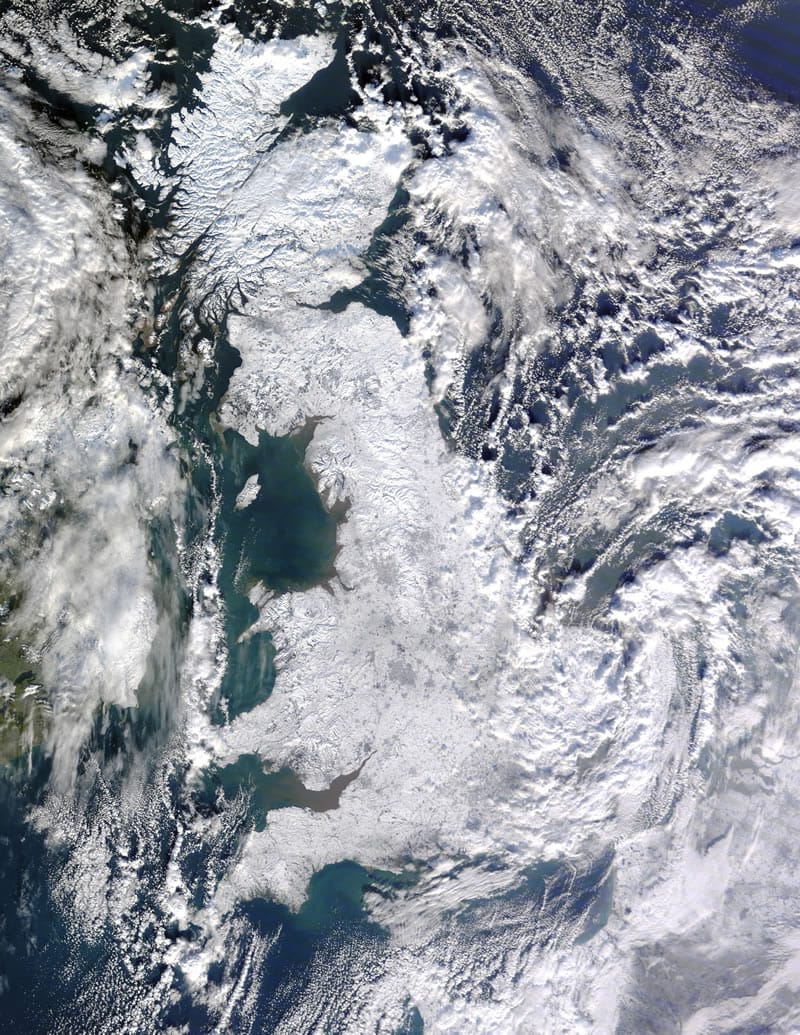

This was an interesting picture from 2010 when the whole bloomin’ country was covered in the stuff!

Snow in the UK, the whole of the country was covered at one point

It might well have been this that made Scotland adopt the Structural Euro Codes in 2010 and that England is following suit. Along with the rest of Europe and several other countries such as Russia, Algeria, China etc.

When we design a roof we’re looking at the strength of the timber used, in our case Northern Spruce. We then look at the angles and compare that with the intended roof covering which is always shingles. Lower than 10 degrees WILL result in failure of the shingles. You may not find it for a year or two but they WILL fail. Watch out for low pitch roofs with shingles, you will need to use under-roof membranes and a lot of glue to make sure they seal. They will not be doing any good on their own.

Angles play a huge part, for instance for every 10cm we can go higher in the roof pitch we can get an extra 5 kg in supportive weight. This makes a massive difference when calculating the strength of a roof on a log cabin.

When we have a ridge height of 2.59cm in the example above there is a reason for it. To reduce the height lower, it would not be strong enough for the snow loading calculations we work to or enough of a pitch for roof shingles to be effective.

Weight of snow

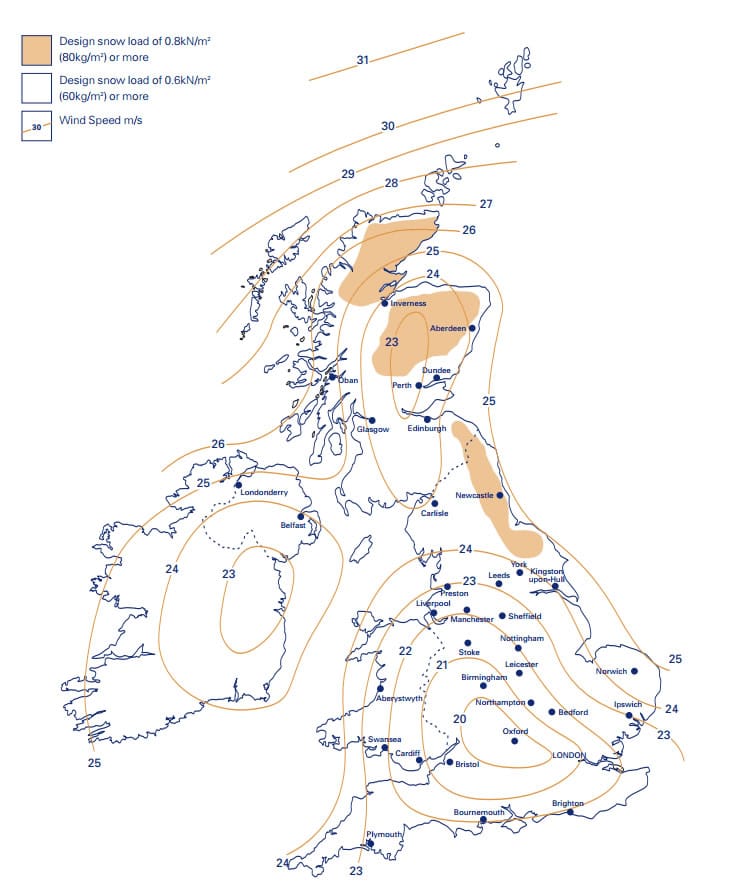

In the UK we haven’t really been worried about this, but it does seem to be worsening. Here’s an interesting map:

A map showing the snow loading requirements in the UK

This map is showing the required snow loading calculations that should be met for a residential property in the UK. You’ll notice the maximum is 80 kg/m.sq. Thank goodness Tuindeco cabins far exceed these.

December 2010 was exceptional in the UK’s snowfall. At one point 60cm fell over night.

Fresh fluffy snow is about one tenth of the density of liquid water. One litre is 1000th of a cubic meter. One litre weighs 1kg. This means that 10mm of snow is equal to 1mm of water.

Therefore if we look at our 50cm on the roof the loading is 1m.sq x 500mm deep / 10 = 50kg

So, overnight you have 50kg sat on top of each 1m.sq of your roof.

As snow settles it will change form several times depending on temperature and time so the weight of the snow on the roof can become heavier due to compacting ice crystals.

You can see from this why the UK has a snow loading requirement of 60 kg/m.sq and higher in some parts.

As I’ve mentioned, for garden buildings in the UK there are no standards at all, we can make what we want, out of whatever we want and it’s great for you if it’s to a price point. It may be a bit of a problem down the line though if we carry on having heavy snow falls.

Also it’s worth asking your insurance company if a garden building is covered for structural damage caused by snow loading. I bet it isn’t!

A Log Cabin Roof Costs

Lets go backwards, let’s pretend you’ve found our buildings or even another supplier but the price just doesn’t match up to the REALLY competitive price. Then let’s pretend we do not have standards to meet and we’ve got to match it, here’s some figures for you to consider:

- Every 10cm / m.sq higher cost us at the factory £7.50 (ex VAT)

- OSB is 80% cheaper than Tongue and groove Spruce.

- Pine is cheaper than Spruce

- 16mm – 12mm is cheaper than 18mm

- Cutting a purlin in half is 50% cheaper.

If Tuindeco were not constrained by standards in Europe but made solely for the UK everything could be so much cheaper. There’s a lot of cheap cabins out there, trouble is they’re not as cheap for the consumer as they should be bearing in mind where the costs are cut.

Log Cabin Roof Strength Calculations

All the good manufacturers list a calculation for the strength of the roof, Bertsch, Lugarde, Scan Holz, Tuindeco. They do this for a reason and it’s an important one that you may not have considered when you are buying a log cabin.

I would recommend, regardless who you are buying from that you ask them what specification they build to. The UK standards for building construction asks for a minimum of 60 kg/m.sq and 80 kg/m.sq in some parts of the UK. Your log cabin should at least comply to this.

Tuindeco design cabins with a snow loading of 110 to 140 kg/m.sq and this makes for a very strong roof indeed. This calculation is reflected in the ridge heights, strength and number or purlins and the thickness of the roof boards that are used.

Your log cabin should be designed to at least the UK snow load building requirements. Ask your supplier what the snow loading specification is and ask for a reassurance that your roof will not sag – Ever and regardless of ‘Extreme’ weather conditions!

‘Extreme weather conditions’ is the excuse that will be given when sags start to develop as is ‘Out of Warranty’. This should not be the case in your log cabin or indeed any garden building if it was designed correctly in the first place.

Extreme snow loading perhaps but it is something to consider!

Installation of a Log Cabin

As well as the loading calculations you’ve also got to be able to get on the roof and install the building, you’ll also need to do maintenance on it over time. All log cabin roofs should be designed for this. Specifically ask your supplier if this is part of the design intent for your log cabin.

There are a lot of cabin roofs out there that you really wouldn’t dare to stand on. I’ve known fitters refuse to shingle roofs because of it.

Make sure there is a design intent that allows you to walk on the roof for installation and maintenance

Hi there

I have a Tuin Ulrik cabin that has been in my garden a few years. I am planning on adding 4x solar panels to one elevation. Each panel is 22kg in size and about 1.98sqm in area. Would adding 88kg of load to the roof cause any issues, and if so, are there any recommendations you could make?

Hi Paul

Thank you for your message regarding adding solar panels, This is an interesting topic

Strictly speaking all of our cabins are made to meet Dutch/German snow loading limits as this page describes, Some Uk supplies do not meet this standard. You panels should not cause any issues but if in any doubt you could consider laminating extra timber to your roof purlins for added strength and peace of mind

Hope this helps

Hi there, I’m currently planning the upgrades to my garden. As I live in the countryside I would love to incorporate a grass or green roof into my outbuilding design. This requires a 60 to 150 kg per square metre load bearing roof. Have you been involved in this discussion before with one of your log cabins?Thanks,

RIchard.

A sedum roof can be very heavy and any building that accepts it will need to incorporate additional roof purlins. This can be accomplished by having a bespoke building made. Alternatively additional support can be added using joist hangers.

Hi Richard. Further to this comment on sedum roof. Can you confirm if the Wolfgang log cabin would require any further supports? I’ve done some extensive research on various sedum green roof suppliers and they estimate around 60kg Of load per meter squared for a saturated roof. this includes the weight for all substrate.

When using Sedums I would always recommend adding extra purlins, with a full down pour and the sedum matting sodden there is an awful lots of weight up there.

Would it be possible to use clay tile a Tuin log cabin roof, or would the weight be too much?

It does depend on the building. Our larger ones are designed to take tiles, the smaller ones will not be able to without adding additional roof purlins.

I’m thinking of a summerhouse, but can’t see how the shingles are held in place ( I may have missed it!) . Also as I am in a fairly windy and occasionally snowy area I just wonder if they are going to lift along the edges. Many thanks.

Alastair

Please have a look at this page: Roof Shingles there is a couple of videos on there that show how they are fitted. Using shingle glue is a good idea in exposed areas.

Richard,

When my Peter cabin arrives I am planning to use two screws to fasten each roof board. Is it necessary to leave a small gap when fitting the tongue and groove boards together, to allow for expansion? I have watched the videos and the fitters appear to fit them tight.

PS: brilliant website.

It is a good idea to use screws in the boards if you are intending to take the log cabin down again at some point in the future, this will save damaging the boards as it is disassembled.

Regarding a cap between the boards an installer needs to consider the time of year. At the height of summer the timber will have a low moisture content and it can be expected to expand in the winter, therefore a gap will be needed.

Conversely at the height of winter the timber will be at it’s maximum moisture content and will not need a gap, if you did have a gap come summer it would be too large.

Hi we just purchased the Liverpool log cabin. After watching the various videos I noticed that you use nails. Apart from the roof shingles, can I substitute the nails for screws? i.e. on the main t&g boards for the roof. Also can I use a paslode nailer or finishing nailer for other parts?

Screws are a good idea but they will take longer to do. If we are putting up a show building or fitting for a customer who expects to move we will always use screws in the roof boards as it will come apart easier. I’ve tried nailers and i really don’t like them, they’re heavy and can fire through too much. I recommend to all installers to nail by hand.

Do not ever use staples in the roof as I have seen before. Also I don’t like the in the shingles but I know a lot of installer will use. In all the buildings I installed I would hand nail everything to ensure I would never have to see the customer again, no matter how nice their tea maybe.

One last thing, two nails in each board at each junction will stop the boards moving. Some fitters only use one and then have to relay the roof in the winter when it’s curled.