Introduction to Insulation

If you were one of my customers and you were buying a lovely new log cabin from me, especially one of our thicker wall log cabins such as 50mm upwards, I would be strongly urging you to insulate at the least the floor of your new log cabin. I would also try to nudge log cabin insulation for the roof as well.

You may also be interested in this post on double glazing, R and U values and Log cabin thermal properties: Double Glazing in Log Cabins

The benefits are obvious for you. You’ve decided upon your building, you’ve weighed up the benefits of the thicker logs and of course the double glazing. But, you lose a lot of heat from the floor. Additionally, the cold rises up and, of course, loses loads of heat through the roof. Ideally we want these areas insulated and to the same or similar as the wall thickness.

As of recent, we have also started selling Insulation Kits for Log Cabins. These include all of the necessary materials needed to insulate both the roof and floor of your Log Cabin. While we offer these kits ourselves, you may want your own insulation supplies from a local builders merchant. I’ll explain what you need to do this along with advice on insulating your log cabin ready for the colder months.

I like the Celotex brand of board. I’ve used several types over the years but get on best with this one.

Here’s a link where you can download more details on the product: Product Guide

I know lots of other manufacturers do a similar product, some better and some worse. That part is up to you but I prefer a solid fibre board to work with as above.

Of course there are lots of ways to accomplish an insulated roof and floor. Some fitters favour adding it underneath the roof and boarding it out thus keeping the insulation in. Some will put a frame on top of the roof and use rockwool and ply over the top. I have never used these methods as I can’t see the benefit other than perhaps a saving in the insulation material cost itself.

So, my rough and simple guide on how to insulate your roof and floor of your new log cabin.

Insulate the Floor

A quick one before explaining this: Have you considered a DPM? A damp proof membrane either within your base or on top of it. It’s well worth it and prevents any damp coming up and into your building. (http://en.wikipedia.org/wiki/Damp_proofing)

I build my log cabin as usual on the 44mm tanalised timber foundation beams we supply with every building. I’ve now completed the build. What’s left is laying the floor down and applying the roof covering. If I’m using a floor pack I will set out my floor bearers as normal. I then cut up my insulation board which I’ve ordered from the local builders merchant at 50mm deep. This sits perfectly between and within the bearers, the joists support my build while the insulation boards supports it. If you want to be exact to the joists then use 40mm.

Now I simply lay my floor boards as normal, happy with the insulated floor.

Obviously you’ll need to work out how much board you need with a simple calculation of length x breadth to find the square meter and order the equivalent from your local builders merchant.

Insulating the Roof of your Log Cabin

The roof is a little trickier to do and takes a little more work. Before we start you need to decide what thickness of insulation board to use. 50mm, the same as the floor is very convenient and often used. You could also go up to 70mm to gain the same R value. I have also used 100mm when specified by planners. Regardless the same principle applies.

Work out how much you need by calculating one side of the roof area and times it by two. As well as the insulation boards you will also need to order longer clout nails. These need to be long enough to go through the final roof surface, insulation and into the roof timber boards. If you’re using 50mm insulation then order 65mm nails for the flats of the roof and 70mm clout nails for the ridges.

Lay the boards so they are flush with the leading edge. Bare in mind this is going to be exposed so consider how you’re going to cover it. In this example we were using 50mm board and turned the roof trim the other way up:

You can also cover this portion later with additional timber but it is worth considering it at this point. You may need to source locally the additional trim timber.

Now lay one layer of insulation boards and fix into place using one clout nail in each corner and one in the center. You can then felt or shingle it up to that first board. Don’t be tempted to do the whole roof with the insulation as you will eventually have to get on the roof to tile or felt it and with the whole roof done it can be very slippery.

Once a board is complete with tiles or felt move on to the next and carry on adding boards and tiles until you reach the top.

For tips on shingling your roof please see this post: Tips on how to fit Felt Shingles on your Log cabin

The last consideration is the bargeboards to the front and back. You can either move the supplied one up or double up the barge boards as below. Again you may need to source this additional timber locally:

The same principle also applied to hipped, octagonal and hexagonal roof. The only slight difference is that you will finish the corners of the ridges slightly differently where by you will cut them flush with the end of the roof boards. You will then cut a fillet to fill in the ‘v’ that naturally forms.

One last tip, if you haven’t got a timber saw or a proper board saw, your wives bread knife works a treat for cutting the insulation boards!

You may also be interested in this post on double glazing, R and U values and Log cabin thermal properties: Double Glazing in Log Cabins

Please see the following article of how to make insulated walls, partition walls and how to use thicker insulation in the roof: Dealing with expansion and contraction in Log Cabins

Finishing the Leading Edge

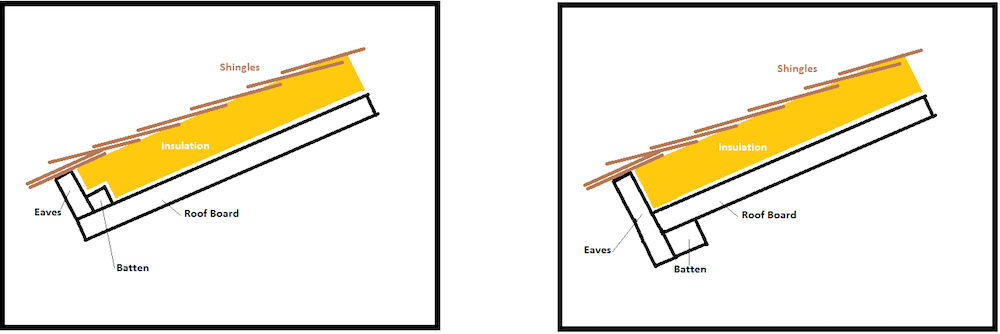

Recently I have been asked for more details on how to finish the leading edge of the roof, hopefully this sketch will give you some ideas:

Ideas for finishing the leading edge of the roof.

If you have enjoyed reading this page then please come and take a look at the log cabins we sell. If nothing else, it will help you understand the possible designs.

Perhaps you have some follow up questions. Please make use of the contact form below and we will be happy to help.

Hi,

I’m going to be building the Shannon (4.5×2.5) log cabin and planning on 50mm Celotex insulation on the roof. I am trying to work out how many Celotex sheets to purchase. The cabin details show 14.6m2 roof area and I’ve found on another blog on here the roof dimensions are usually 20-300mm overhang but I don’t know if that is on each side or overall.

Would you be able to tell me what the roof dimensions would be for the Shannon 4.5×2.5 cabin?

Many thanks

A quick, rough calculation I tend to use is (L x B)x1.3. For a more efficient way you can ask the main office for a set of plans before your build. You find the length of the roof board, in the case of the Shannon it is 1550mm. Then look for the length of the purlin, which in this case is 4700mm. Therefore each side of the roof on the Shannon is 7.285 m.sq.

Hi

We’re due to take delivery of Hazel with included EPDM. On the room I intend to add 50mm celetex held with 65mm clout nails.

Is it ok to then to stick the EPDM directly on the celetex? Also with the additional height do I receive enough EPDM to cater for this and still cover roof and side?

Thanks

Stephen

Ideally you will have a board of osb or ply on top to stick it to. You maybe able to stick it to the insulation but you will have indents at the joins.

Just in case anyone else is wondering “will I have enough edpm spare to do 50mm of insulation and board over the top?” the answer is an emphatic yes they supply you with alot of spare rubber, at least half a meter spare on each side.

Hi Richard – great info on here, thanks. I will be ordering the Aiste within the next week and have a couple of questions pls. Rather than using Celotex below the shingles and within the flooring joists, I am thinking of using the foil insulation. I thought this foil stuff would be much easier for the roof than Celotex!

Do you think I should lay the foil over the flooring joists before laying the flooring? Would the 18mm rather than the 26mm floor be OK with using the foil?

For the roof, do you think foil on top of the roofing and shingles on top of the foil?

Apologies for all the questions. Thanks very much!

I haven’t used the foil but I know people do, mainly in our shepherd huts. I’m not sure about using it on the roof as I don’t think it will be solid enough to fix the shingles, you may want to add board on top of the foil to fit the shingles. 18mm floor is enough for most applications, I think I’d still put the insulation in between the joists rather than on top.

Thanks for this post its been very useful, If I were to buy a Tuin cabin on 47mm bearers and insulate as suggested the 50mm celotex under the floor would end up sat directly on the concrete slab with no air gap under it, is this correct?

This is correct and is not a problem so long as a good seal is maintained around the perimeter and the use of a damp proof membrane.

This is a great guide and I intend to insulate the floor of my new cabin as described, the roof however is slightly more tricky and I wondered if you could comment on your suggested route.

I am awaiting delivery of a Jannie cabin which has an outdoor section of roof as well as that over the cabin it’s self, I could insulate the whole roof but this seems a little wasteful and a lot of work for half of the area to be covering an open seating area. Is it possible to insulate between the supports in the actual cabin area only ? I thought this approach might allow me to use thicker than 50mm insulation on the roof area also? is there any reason not to and concerns I should consider if I chose this approach ?

Would be thankful for any insight

I wouldn’t recommend using anything thicker than 50mm on the roof, if you do you will need to add framing and ply on top for the shingles, this adds weight and is not necessary.

There’s no reason why you can’t just insulate the cabin area but you will end up having a step in the roof where the heights change. Or you will have to create a frame and ply to match the height of the insulation. For ease of installation I would be insulating the whole roof.

Hi Richard, just ordered a rorik cabin 58mm 4x3m with composite foundation beams and the flooring pack. I have a few questions about the fitting of these with insulation.

I have 50mm celotex for the floors and roof and would like to confirm a few things about fitting them.

First the floor you said will sit proud of the joists, I will be using this cabin to store alot of heavy weight items and shop equipment what would you recommend to deal with the added stresses and weight? As the load bearing abilities of celotex won’t be enough.

In my shed I used 3×2 as the joists with t&g flooring on that.

Now the roof, my plan was use a 2×2 batton around the perimeter of the roof then fill that with the celotex and board over with 18mm osb3, Then I have the iko cold bitumen felt adhesive stuff in a tin for the shingles and iko underlay 3b for directly on top of the osb then the shingles on that.

All of my neighbours have cats and we have trees and high winds in the area. Which is why I was thinking the osb would be a good second protection from cats, branches, rocks, children and what ever else gets thrown at the poor thing lol.

Thanks in advance

David Greenberg

If you are concerned about weight normally you will place the joists closer together, if you are worried using the 50mm insulation then you can use thicker joists and closer together.

I do not think you will need to worry about battoning and boarding the roof for protection. The shingles are very hardy and will easily cope with things on them, animals, the odd falling branch and leaves. It’s a good idea to use bitumen glue on the overlaps but also make sure you nail them down correctly.

Hi Richard, I’m planing on insulating the roof of the 40mm jenny log cabin. I’m gonna be using 50mm celotex and plan to put 11mm osb board on top of the insulation. would this be too much weight on the roof? should i go for a thinner ply on top of the insulation. Would i need a breathable membrane between the t&g roof boards and the insulation?

I wouldn’t add the osb, there’s not really any need to and it adds weight where it is not required. Using insulation and shingles on top i have not found a need to add a membrane.

Hi Richard

Really good article here – a real wealth of knowledge (which im hopefully going to leverage!) Im planning on getting a 44mm log cabin for use all year around as an office, so i want to make sure its suitable for winter.

I plan on using foil backed Celotex 60mm as recommended on the roof (cold roof) and flooring. I also wanted to build out the walls and use 60mm boarding for this also. I have seen a few places that recommend NOT to insulate the walls as its not needed – however, i cant see how insulating it would be a bad idea.

my plan is a breathable membrane against the inside of the logs, with a spacer of approx 10mm for airflow, which the boards will then sit on top of. I will then clad add my internal cladding (shiplap or some other sorts).

Do you have any advice / pitfalls to look out for with this plan? It would be good to hear your experience of heat retention with 44mm logs on the walls, as im not a fan of the ‘dont insulate the walls’ theory.

With thanks

Jonathan

You don’t normally need to worry about insulation of the walls in a cabin of 40mm or above thickness. But, if you would like to as some people do it’s important to consider the expansion and contraction of the logs and not to inhibit this natural movement. Please see this article which offers some advice: Expansion and contraction of log cabins

Hi, I’m considering buying one of your Trevor

Clockhouse cabins (5.5×4) because of its high roof space and would like to add a loft on one end of the cabin. Do you have any advice on that in terms of internal support etc?

Also, is it possible to change the position on the double door so they are at one end, not in the middle? There is an apple tree which i don’t want to cut down quite close to where the door opens?

Thanks

With any log cabin you have the option of having a bespoke one. With that they can incorporate joists into the roof so you can create a loft, you can also choose the position of the door.

If you don’t want to go to the expense of bespoke I would suggest using joist hangers from the top logs and creating a loft space.

The door position cannot be moved as a standard building.

Thanks for that speedy response Richard, what depth of joist would you suggest for a 3.5 4m span. Taking the Trev Clockhouse as a template, what would the extra expense roughly be to go bespoke? For example, not having clockhouse gable, or windows on one if the sides, moving the door to one end and adding a couple of levels of logs to increase the height…..and what would the lead time be?

Many thanks

Mike

It would depend really on what you’re putting up there but generally around 140mm x 45mm and about 400mm spacing should be ok for most applications.

I think bespoke is about 20% more than a standard building.I suggest emailing the main office with your requirements and they can give you a quote.

Hi Richard – I recently asked you on this blog about adding a loft space – this was for the Ben Clockhouse. You did reply about using joist hangars on the top logs if I was adding my own loft at a later date. I’m looking at getting a bespoke design with the doors moved to one end, but still want to add my own loft later to keep the current costs down and have a couple of questions:

– 1 – the loft will be above the doors at one end and I’m concerned about there being not much support if the hangars are placed here because of the door opening below. What would be the best way of bracing this. I was thinking of a 2×6 or 2×8 from front to back, and then putting hangars on that to go from there to the end wall. Would that be ok?

– 2 – I’ve been talking to your guys about supplying an extra couple of levels of logs to raise the height a bit. In this case, I wouldn’t want to have the hangars from the top as I’d not be using all the extra space this would create. Is there a way to install hangars before the top level?

Sorry about all the questions, but I just want to make sure I have everything right before I order.

If you’re going for a bespoke option I would suggest you have the floor joists incorporated into the design. It is going to look far nicer and be stronger and take away a lot of the possible problems.

Hoping to get Leeds on order shortly. I had assumed a vapour barrier between the roof boards and the insulation but this is something you dont recommend. Similarly i am installing on a timber frame base and was planning an inverted one below the insulation to double up with the DPM. Any reason i shouldnt do this?

I didn’t say I don’t recommend a vapour barrier, simply that I have not used ones in my installs and have never had a problem not using one. We usually support the insulation with battens within the frame and have not added and extra DPM under there before so I do not know if this would cause a problem.

Dear Richard,

MIA 70MM log cabin floor question about the hieght of the insulation and bearers plus floor.

ive ordered the composite foundation for the building too.

please can you advise me on the max hight of foam plus OSB floor i will get away with on this log cabon before i run into a problem with the door. i was planning to use 75 mm floor studding, 55 mm celotext foam between it and then add a 22mm osb to sit on the stud work, which means from the concrete base i get a hight of 75+22 = 97mm. please advise if i need to reduce this to avoid any issues with the hight of teh door thanks.

When using the normal floor joist and 18mm boards in the floor packs the floor level will be about flush with the door threshold. If you add 27mm floor or thicker as you are doing you will have a lip / step above the threshold. Most people will shape this by putting a chamfer on it. As you are using even thicker joists you will be quiet high and will need to chamfer it.

thanks i probably dont want to chamfer so i will istead maybe go 50mm floor bearers and 50 to 55mm celotex and float the osb on toap so it will be a max of 55+ 22 = 77 mm max. but i also was planning maybe underfloor heating and laminate in there so that would add hieght. As an alternative strategy to my solid concrete base, i was wondering about instead putting a brick line or spare railway sleepers on there to raise the hieght of the cabin. is this madness? i was thinking a brick line to sit the compposite was a good idea purely because the concrete base is slightly larger than the log cabin and i am concerned about water removal from at least one side… ie.e whats you best solution is someone wanted to raise the cabin door hight if they didnt want to chamfer is my question?

If you are going to have underfloor heating then I think you will be better to just have the concrete base, then insulation, heat mat, screed and laminate (other layers such as glue maybe necessary). A brick plinth works well and look lovely on the perimeter especially with the profiled foundation beams. You could raise the door height by cutting into the logs above it, then you would be taking some strength away from the top two logs that tie the walls in. You would then have to put a log in below the door. The best solution is either a heated floor off the concrete base or brick plinth if you want thicker insulation.

im intrigued but he idea of celotex plus heat mat plus screed. i would be rubbish at doing the screed as im no sure i can get it level, any ideas? so if i did this would i need to frame the celotext still? i assume i dont? would i be able to simply lay teh celotext on DPM, then heaters (electrical heaters) on celotex sheets, then 35,mm screed or more? then laminate?

Search the net for ‘underfloor heat map’ and then look under images, you’ll see how they recommend doing it from various manufacturers. You would still have a DPM in your base but you would do away with the floor joists and floor boards / osb. There is several self levelling compounds about which removes the skills needed to get it level.

Hiya when we did our cabin we asked for the hight of the door threshold and when it arrived it was different to what we had been told. This was a problem with the insulation and flooring we planned.

What we ended doing was packing under the door and cutting a notch in the log above.

This worked fine for us been up a year no problem.

Hi Richard

Hope you can help. I have erected my aste cabin now just working out what roof insulation to go for. I am looking At celotex tb40000 40mm. What size clout nail do you recommend for this ?? Also I have read on other blogs that it is advisable to put a vapour barrier on between the roof boards and the insulation any comments on this. ?

Thanks

Brett

You’re going to need a nail that goes through the insulation and into the roof board, taking into account the thickness of the shingles so probably around 55mm. I would get some slightly longer ones for the ridge tiles. Some fitters do like a vapour barrier, I’ve never used one and I’ve not encountered any problems without one.

Hello, I am waiting for my log cabin to be delivered and just completing some research on insulating it. I know the cabin will expand, contract and move over its life. If I baton the inside walls then put thermal insulation between the batons and then clad over this with tongue and groove boards will this cause issues with the movement of the cabin? Will it restrict the movement due to making the walls stronger with batons? I need a fully insulated cabin as I will be using it for a snooker room. It will be used all year round so needs to be insulated well. I hope someone can advise. Thank you.

If you fix the logs together you will have problems with the movement of the timber. But you can overcome this by adding expansion slots, I try to explain this here: Dealing with expansion and contraction in Log Cabins Normally cabins of 40mm plus it is enough to insulate the floor and roof for all year usem with of course a suitable heat source.

Hi Richard

When laying celotex for the floor insulation, what do the insulation boards rest on.? I know one of your ‘main’ competitors provides clips to secure the insulation boards to the joists so do the Tuin cabins have a different base set up that doesn’t require this?

Ther advice I give on the blog is for all log cabins, not just Tuin ones. Generally a cabin will be placed on a concrete or paving slab base, made to the foot print of the building. The cabin is then built and then the floor is added afterwards. The insulation sits on the base and in between the joists with the floor boards on top, fixed to the joists. I don’t see any need for ‘clips’ unless it is a very thin insulation or something other than an insulation board.

What about if the joists of the base are higher than the floor below and there is a gap between them ??

If that was the case I think I would use off cut shingles to raise them, or timber slats or anything needed to take up the gap. It would be unusual though to have joists over 50mm. If you did it would be a larger 70mm, 90mm, 120mm, building as for a house that needs greater insulation and a different system.

So the insulation would sit on potentially wet concrete or slabs?

If the base is done badly, has a slope or joined to something draining into it then potentially yes, if this is the case the base needs to be reconsidered or a timber frame is used.

Hi Richard, I’m all ready to purchase the Justine cabin but my lack of understanding of the floor insulation fit and base is holding me back from buying.

Please can you describe what I would need to do here as my DIY knowledge and skills are pretty basic, I will have someone skilled helping me build it luckily.

So, I intend to use a Plastic Grid base system filled with Pea Gravel. This I believe has a DPM underneath.

I plan to have the standard foundation – is this sufficent? And also the 26mm floor.

I will likely buy 40mm celotex insulation as i think you mentioned this should sit flush with the joists/bearers (are these the same thing?).

So in the last post I think you are saying the celeotex would sit directly onto the pea gravel filled plastic base. Is that correct? Does there need to be any DPM between the plastic base and the build as well as under the plastic base?

Sorry about all the ‘basic’ questions but need to understand what i’m purchasing in my own head. Thanks

Using the plastic grids and pee shingle means you can’t really insulate in the way I describe. You’re not going to be able to seal your base and it is likely to be wet. If you are certain you are using the grids then I think you will need to add bearers thereby lifting the whole cabin from the base to allow it to vent. Effectively creating a timber frame base, you then insulate in between the bearers.

Hi I used the plastic base and pea shingle and was not happy with it, you have to be bob on with the leveling of the ground. In the end I made a 6×2 timber base for the cabin to sit on on top of the pea shingle and cell and I am much happier.

My tiles when overlaid make hexagons. Some of them, despite being bitument backed, haven’t sealed to the tile below and the nail heads are just underneath the lowest part of the hexagon if I lift them up, so I imagie it must be getting in there. I’ve added some more sealant under the tiles over the nail heads so hopefully that will sort it.

Bitumen glue is ideal for this and extra security.

Thanks, I used roof & gutter sealant, it’s helped but still get an occasional drip, will get some bitument glue to help with any remaining problem areas.

Hey Richard

I am about to take delivery of my cabin with a patch roof . I was looking at using a foil space blanket type product ion the roof as thought this may give me better performance than hard material and also making it thinner hence no need to change the clout nails ??

I am looking at siting the area on a deck I have. my question here is would it be better to remove the decking boards and just utilise the frame inserting a DPM on top of the decking frame or should I just go on to op the decking boards. and then get a 50mm insulation board.

I’ve heard good reports on the foil type insulation but I haven’t used it myself, I think you may need to consider adding a thin ply or similar on top as I think the foil will be too soft to support the shingles.

If you sit the building directly on top of the decking you may have gaps caused by the ridges in the decking? If so I would make sure these are filled. The

Hi, I’ve recently ordered a Charlie Log cabin with floor pack and looking at floor insulation. Can you advise on the depth of the floor bearers. Your blog above reads as if they are 40mm but you install 50mm insulation so I’m confused as to how the insulation does not sit 10mm proud? I assume I’m misunderstanding. I’d like to buy 50mm insulation but need to ensure i can get the floor onto the bearers of course. Thanks

I think i’ve mentioned in a previous article that the insulaton, if you are using 50mm, will sit above the joist. But using something like celotex you will find it carries the load very well and the joists are simply there to hold the floor boards in place.

Hi Richard, I too am confused by your info and your don’t appear to have answered this question. Does the Celotex compress on being nailed down? Do you have a10mm gap? If the flooring is sat on the Ceoltex and it’s 10mm proud…why would you do that?

I’ve recently ordered the Bayern.

It will not compress when nailed down.

Yes you will have a gap between the joist and floor board. The floor boards are supported throughout by the celotex, the nails in joists are fixing the flooring.

You’d do it because you want to put 50mm on the roof and it makes sense to buy just one size and use throughout thus keeping your costs down and the efficient use of offcuts.

If you don’t like this either add larger floor joists or use a thinner insulation board.

Richard, it’s worth mentioning that this 10mm gap also prevents cold bridging between the joist and boards, so doubly useful.

Hi Richard, We have just taken delivery of our Chloe cabin. we intend to insulate the roof on the outside using Kingspan or Celotex 50mm boards. I originally thought I would “sandwich” the insulation between the roof boards that come with the cabin and a think ply for example. My reasoning was regarding clout nails through the shingle and insulation. I noticed you say if 50mm insulation is used there is no need to sandwich the insulation and just use longer clout nails obviously. do I need to be concerned about the insulation compressing when I knock the nails into the roof boards so much so that the point of the nail shows inside the cabin and would there be a wave type effect when looking along the roof at the shingles if due to compression of the insulation boards the nails were knocked in at different depths?

I’ve never used these boards an maybe I have dreamt up an issue that wont actually exist in practice.

By the way the delivery service is brilliant. We live in a very rural location and again in my negative everything will go wrong head it was going to be impossible for your delivery guy to get here. It took 5 mins from the lorry pulling up at the end of the road. Brilliant.

Many thanks

Len

When you nail you should be nailing so hard that the indent the board, it’s always best to have a practive first, you’ll soon find it’s quite straightforward.

Would you use polystyrene board under roof shingles?

https://www.wickes.co.uk/Kay-Metzeler-General-Purpose-Polystyrene-EPS70—2400mm-x-1200mm-x-50mm/p/210824

You can use anything you would like, the main consideration is getting a good fixing for the final roof covering. You also have to work on the roof and the polystyrene may well not cope well with that.

Hi, I was wondering when you put insulation board between the floor joists how you stop it falling through? We have a suspended wooden raft so there is a drop underneath. Also – whether to put some membrane under the raft so nothing can crawl up inside

It’s certainly a good idea to have a DPM under you base to stop any moisture coming up. You can secure the insulation with battens, wire, or another board.

Hi Richard, we have a large 7×4 cabin, and we have 75mm Celotex to go on top of the 20mm t&g roof boards. We also have shingles to go on top of that. I have not been able to sort any ‘clout’ nails that are long enough (90mm to 100mm), so we have had to get 90mm galvanised ‘Round Wire Nails’. Would this be OK? From my calculations we will need to hammer in 1300 nails!!!

If you re using insulation over 45 – 50mm I would only frame the roof and cover with ply or osb and then fix the shingles to that with roof clout nails. I would not recommend nailing a thicker insulation.

Richard have you covered this method in a blog post describing how to build the frame, batten spacing, etc? I can’t find anything on this.

The frame is just the sae depth as the insulation and to the same dimensions of the board you are putting on top, it is just to secure the board so the roof covering can be fixed to it.

Hi Richard we have just had delivery of the Layla log cabin and wanted to confirm that we could happily put 1/2 inch ply on top of the 50mm celotex on the roof. We would then fix the shingles onto the ply. I think from the above comment it should be Ok?

Thanks Lucy

If you’re using 50mm or less of celotex or similar then you do not need ply. If you have a flat roof building you will though need a thin ply to fix felt or glue EPDM.

Thanks Richard. We are in a fairly exposed position and it can get very windy as we are easterly facing. We were concerned that 65mm clouts might not hold the shingles and celotex down well enough. From all the reading I am doing we are possibly worrying too much but thought we would ask as you respond so quickly! Thanks

They should work fine, I’ve fitted in some very exposed areas and not had a problem. But, make sure you use a bitumen felt glue as well, especially in the corners and the leading edge of the roof. If you are very exposed please also consider adding a storm kit or some sort of bracing just in case of very, very high winds. In very exposed areas I also screw the purlins into the top wall logs.

Hi Mike,

I’m on the same situation with my cabin build. I hadn’t spotted the advice on not exceeding 50mm insulation until I bought 75mm and have also struggled to find long enough clout nails.

What did you do in the end? Do you have any advice/photos you could send my way please?

Thanks, Joel

Hi Richard,

Would you recommend using one of the multi layer insulators such as Superquilt instead of Celotex? as they are much thinner PS I dont work for Superquilt lol

Personally I have not used it but I know customers have done so with good results, being thinner is good and it also gives higher thermal insulation.

Hi Richard – I`ve ordered a cabin from Tuin due soon and looking at using breatherquilt under the floor and on the the external roof. I`m thinking of putting a DPM under the floor joists (wooden deck underneath) then the breatherquilt insulation on top of the joists, then the flooring – so effectively the insulation is continuous between the floor and the joists. Would that be ok in terms of air recirculating?

Also, I`ll be using breatherquilt under the shingles instead of 50mm insulation, as one 12 mt roll will do the whole cabin….

That sounds ok with the floor. I think may need to add a thin board on top of the roof insulation as it will not be firm enough to fix the shingles to?

Hi there did you use product and how did you do the roof ?? Did you put a sheet of ply over it ?

Hi Richard

I thought I had already posted this but cannot find my post so apologies if this is a repeat

We currently have one of your wonderful log cabins a Rosenhiem that we have been using with a hot tub in for the last few years. The hot tub is on its way out so I will be looking to convert the cabin to a home office as I work from home.

Proposing to insulated as follows and would welcome your comments

Floor:

50mm cellotex (type) in timber frame – basically create a floating floor effect. This is currently on a Concrete base so will DPM first then frame and infill with cellotex

Walls – Fit battens to walls (taking into account expansion – read your other posts) – Fit foil insulation to back of 12 mm ply – fit ply to battens (make a second skin in other words) – working on basis that the gap allows air floor between outer logs and inner insulation. – This will make the walls at least 50mm thick with air gap and foil (wondering if need to insulation as well as ply?)

Roof – I was thinking of following the same approach with the roof as I am planning to do for the walls but worried about condensation

Would really welcome your advice as it was invaluable when building the cabin in the first place (not sure if my review is still up there)

I think you’ve got everything covered so long as you rightly allow for expansion and contraction in the wall logs. The roof is always a sticking point with me. I like to put all the insulation on top as I do not have worries about condensation. If you are going to put in under the roof you will need an air gap above the insulation and I think I would also put in vents in the void to allow free air movement.

Thanks Richard – I installed some vents to allow for the hot tub moisture so I can fit those in the void – Cheers

Hi – will soon be taking delivery of our Annabel cabin which I’ll be attempting to build myself. Just a question on how best to insulate the roof, I see you mention in a few places that the insulation would go on top of roof boards and then best to use OSB on top of that before fitting EPDM. Firstly, what thickness OSB is recommended? Secondly, you mention for flat roofs it is best to frame them when insulating – how exactly do I do that/is there a guide I can read anywhere (pictures always helpful)?

Thanks

The board on top is to glue the EPDM to so does not need to be thick at all, a 9mm board should be fine. Regarding framing this is timber of the same thickness as the insulation fixed to the roof boards. This is of course spaced out according to the size of OSB / ply board you are using so you can fix it to the roof.

Ok great, makes sense – so in essence just creating an equivalent of a floor joist for the insulation to sit between and the OSB board to fasten to?

Yup, that’s correct. Good luck with your build.

Thanks very much! Shifting to the floor quickly, we’ve got the composite profiled foundation beams – will 50mm celotex work well with this cabin and foundation combo? Was planning on putting this between the floor joists but I’m aware the profiled beams are not as deep and thus might cause issues with the door possibly?

You can use 50mm if you would like to. It will sit slightly higher than the door threshold but you can chamfer the last floor board to make it look nicer and less of a step.

I am contemplating buying a log cabin to use it as an extra bedroom. I therefore would like to insulate the floor, roof and wall. You have mentioned a few times about floor and roof insulation but rarely wall insulation.

What is you thought on insulating the wall on the inside with a 50mm celotex, vapour barrier and plyboard (as wall finish)?

It’s not usually necessary to insulate the walls if a thick enough log is chosen. If you do insulate the walls you need to consider the natural expansion and contraction of the logs and make allowance for it in your design. Please see this article which will give you information on this: Expansion in Log Cabins

Thanks for this guide. Can I please ask about vapour control layers and/or breathable membranes, since I am confused by different advice on these. We are aiming to insulate our cabin roof (a 16 degree pitched roof) using Celotex or similar PIR boards on the outside of the roof (on top of the wooden roof boards) before the waterproof layer. I understand we will have a “warm roof”. Do we need either a vapour control barrier or breathable membrane as part of this system anywhere? I notice you don’t mention these in your article. We are also planning to use an EPDM sheet for waterproofing (even though I note that you don’t think these look very nice on pitched roofs!) I am guessing we will need to cover the PIR boards with a layer of ply so that there is something for the EPDM to be stuck to?

Many thanks.

I don’t usually use a membrane as with just 50mm of insulation and then felt on top there is not a need to in my opinion. If you are sandwiching the insulation such as adding a plywood top to stick EPDM onto it is a good idea to introduce an airflow above the insulation and below the upper board.

Thank you, Richard, for your prompt reply.

We are wondering about using Plylok, which is PIR insulation with a 6mm layer of ply on top. It may work out cheaper than buying separate layers of PIR then ply, especially when you factor in labour time. With the Plylok the ply is pre-bonded to the PIR, and we’d glue the EPDM membrane on top of this. So, we’d be unable to create an airflow as you suggest above. In that situation should we use a vapour membrane on the roof boards, before laying the Plylok. (And wouldn’t fixing down the Plylok make holes in the vapour membrane?

Costs are starting to mount up, and we are now wondering about reverting to a ‘cold roof’ system, with PIR between the rafters on the inside of the roof, with an air gap between the PIR and the roof boards. Would this suffice?

Many thanks for your time.

I haven’t used this product before but looking at their instructions they are recommending a vapour control layer on top of the roof before the insulation is applied.

I would not put the insulation inside if at all possible. With it inside you can create horrible problems with condensation build up.

Thank you, Richard. Very helpful as always. If we went ahead with insulation on the outside, and used a vapour control layer on top of the roof, can we still nail/screw through it to fix the PIR boards to the roof boards without completely ruining its function? Many thanks.

It should be fine to fix the boards as any fixing will also seal the hole

Hi Richard, SO have purchased a Meaghan cabin and have it built ready to insulate the roof and floor, I went for the profiled foundation beam which I’m now slightly regretting as it means the cabin sits that much lower to the ground and therefore theres only 45mm to the top of the door step, leaving only enough room for 25mm insulation….hopefully the somethings better than nothing rule applies. My worry is the roof; looking at your ideas above you say that putting the singles directly ontop of the celotex will be fine…wont the celotex end up being damaged with no wood to protect it, especially if im kneeling on it to work up the roof as you describe?

Great info, really helped the build, thank you!

I wouldn’t regret the composite beams, they last forever, they look far better and they help with drainage. If you wish for a larger cavity between the base and floor boards to accommodate insulation you will put the floor joists first around the perimeter so you are not relying on the lip of the foundation beams. You can also raise the door frame slightly higher with a shim under it so becomes level with the top of the floorboard. You could also simply chamfer any step.

Some damage will occur to the roof insulation as you are nailing through it. I haven’t experienced damage on the roof as long as you spread your weight, you could also use a crawling board. Certainly though a knee as the single point of contact will dent the insulation board. You can of course frame and cover the insulation with a board with the shingles on top but this is extra work, extra weight and expense that in my opinion is not really needed.

Hiya Just seen your query with regards insulation for the floor, we were in a similar position with our Karen Cabin the difference being is that they had changed the design thickness of the door threshold to what we were told when planning the base so we did not have enough height to put flooring such as laminate or carpet down.

So we had to shim up the door frame, it works OK just bare in mind that you have to notch the first log on top of the door frame the same as the thickness as the shim you use to allow for expansion.

With regards insulation on top of the roof.

We not going to bother insulating the roof but we concerned about the thickness of the T&G roof boards supplied when they arrived as they do not look that substantial , maybe they are OK for a load such as snow but as our cabin is near a tree and we were concerned about the impact of falling branches damaging the roof boards.

So as a last minute thing we decided to use insulation boards to spread the impact load of any large falling branches.

I used thick 30 mm insulation from Quin Them and used the timber Tuin supplied which were 25×30 on top of the roof to attach the side barge boards to and act as a retaining frame for the insulation, this also meant that we did not have to mess around with the Apex barge boards as they looked OK when we fitted them.

Anyway I crawled sideways all over the insulation with the odd time on my knees with hardly any indentions or damage to the insulation (I am 12stone or 90Kg).

Also we did as another poster suggested by cutting the insulation edge at an angle so that there is not a V at the apex of the ridge this worked well.

You may of thought about it all ready but I ran the cables for roof lights along the roof before I put the insulation on, checked with my electrician for the size of cable and that he was OK with it run below insulation and because its protected by an RCD he said it was OK.

Hope that helps.

Hi Richard,

Your advice is absolutely brilliant. These blogs are invaluable.

As the soon to be owner of your glorious Gijs cabin I have a quick one for you. I plan to follow your advice and install Koolspan 50mm insulation to the roof boards (on the outside). Brilliant and simple. However, As the Gijs has a 2m verandah I think it is overkill to insulate the overhanging part of the roof. Also expensive as insulation is quite pricey. So, I was wondering, how have you tackled this on your Gijs installs? How do you insulate part of a roof?

I guess the simple things is to do the whole roof, but I am loath to waste money. Any thoughts would be very helpful.

Very best

Steve

I understand the cost but it really in the simplest way to do it and insulate the whole roof. If you did want to save money you could add a frame and a board to bring the canopy up to the same level. It would be quite a bit of faffing but could be done.

Our Chloe cabin sits on a timber frame, raised off an old, uneven concrete pad, using adjustable joist supports. The gap between the support frame and the floor joists and the concrete pad varies from 5mm to about 40mm across the whole area. Do you think it is worth laying some dpm under the floor joists before I insulate and board it out? I thought it might be better not too, to maintain a little airflow? Thanks

If the floor joists are incorporated into the timber frame I think I would be applying a DPM directly on top of them rather than underneath.

Hi My log cabin arrives next month. I plan on insulting the roof would I be doing the right thing by using 70mm insulation sandwiched between the roof boards and 9 mm OSB board on top ? Would I need use a breathable membrane ?

For a normal log cabin 50mm should be enough done the way I have suggested. For the bigger cabins, 70, 90mm thick logs then yes 70mm sandwiched is a good idea. I wouldn’t do it on the thinner logs though as you are increasing the roof loading a lot. A breathable membrane is a good idea on larger building insulated differently.

Hi Richard So if I use 6 mm ply to keep weight down instead of the OSB would I still need to use a membrane or not and would I have to frame the roof to hold the insulation in place ?

You would need to frame the roof and cell it regardless. Consider as well the depth of wood you have to the felt nails assuming you are putting shingles on. If you are double layering it, it might be an idea to use a membrane. I only recommend this for the larger 70mm plus buildings.

Hi Richard I am in the process of building a 58 mm Blackpool cabin I am using 70mm celotex on top cell’d with 3×2 with 18mm osb 3 I hadn’t seen this article before ordering material, are you saying the materials I am using will now be too heavy for my building? Please could you reply quickly as I am nearly at this stage of the build.

Cheers

You’ve gone a bit over the top for what is needed and it is quite a bit of extra weight on the roof. But, you have a 58mm building, it is very, very strong and will be able to cope with it.

I have a question regarding the need for a DPM. I know this has probably been answered before on the blog but I’m seeing some conflicting information. I have built my cabin on timber bearers sitting on concrete blocks. So far I haven’t been able to incorporate a DPM and I can’t quite work out where it would go at this stage. Without it the joists will be sitting around 6 inches above the bare earth. Is it neccessary to use a DPM in this situation? Will the airflow take care of any damp rising? The only place I can think to put it is on top of the joists and lay the floorboards on top, but that would mean nailing through the DPM. Is this advisable or would I be better just leaving it out altogether? Any advice would be very much appreciated. Thanks.

Ideally I would still use a DPM even with the air flow, you can then be sure you’ve done your best to stop damp coming up from the floor. You could place it either under or on top of your floor joists. Under would be ideal.

Hi

Some help please.. Why the need for the 70mm clout nails for the ridge? Just about to put 50mm insulation and shingles on the TRUUS and have 65mm clouts, and wondering what is the best way to do the ridge as there will be a V Gap where the 2 x insulation board end, do we fill that with cut insulation in shape of a V? Any ideas welcome. Thanks. – thanks for help.

I like to use longer nails on the ridge as there is more felt to go through, plus the ridge is exposed and I like to make sure everything stays put. There will be a V where the two boards meet, I have never really worried about this as it is directly on top of a purlin and the insulation properties remain the same. If you wish you could infill it with off cuts.

Why not cut the Celotex at an angle such that there is a butt joint over the ridge?

Yes, that’s also a good idea.

Hi Richard

I have just fitted all the roof planks on my 45 mm Clockhouse and intend insulating with 50 mm Celotex. However I am a bit apprehensive at the slope of the roof at 35 degrees. You recommend in your article that I insulate a board at a time and fit the shingles as normal using 65 mm clout nails. However at some point I have to climb on to the roof with my feet and knees providing the necessary friction to keep me in place. Terrifying to say the least. I am concerned about my safety first and damage to the Celotex and shingles second. With only three clout nails holding the shingles surely they will tear trying to hold me in place!!!!

What method/technique would you use or suggest to keep me safe and prevent and damage?

With tall buildings or ones that have a very steep roof pitch it is best to consider the use of scaffolding / scaffold tower and / or a safety harness and line secured to the opposite side of the building you are working on.

I will also use a spare log or a deal screwed to the roof, on top of the shingles I have previously laid to act as as a foot hold. As I move up the roof the log is repositioned. On very large buildings I have used more than one.

Any hole in the shingles can be filled with silicone and grit from surrounding shingles then sprinkled on top of the silicon so it is not seen and remains water tight.

Hi Richard

Thanks for your reply.

Your spare log idea inspired me. I have screwed a length of 2 X 1 ( I am an inches man) to the edge of the roof planking to which I have screwed a length of decking with the other end cut at an angle to secure it tight against the clock tower. As I moved up the roof I added another piece of decking to form the next step. Worked perfectly. I used a left over piece of planking to put under my knees to prevent damage to the shingles and the Celotex.

To begin with and to gain confidence I used a length of rope round my waist and secured to a wheel barrow full of rubble on the other side of the clockhouse.

Many thanks

Hi Douglas, I’m sure Richard will reply but i have literally just gone through this process so thought I’d chip in.

The reason to put the insulation and shingles on one insulation sheet at a time is so that you can be on the wooden roof boards while you’re doing it. Not that you shouldn’t still be very careful, but I felt secure and stable sitting in the wooden boards, for hours on end.

I started in this ideal fashion, going sheet by sheet, however due to weather concerns I finished the first day of this by putting all of the insulation up at once, using a few clout nails to hold it in place without the shingles. This worked well, but made things much much more difficult. The celotex is slippy! Although let me reassure you on one point… It will take your weight. I’ve been scrambling around on it all week and it’s fine. Be careful with knees and elbows, and I ended up taking my shoes and socks off in case the hard soles tore into it, but otherwise it’s surprisingly tough. Incidentally going barefoot also helped with friction on the celotex.

Hi Sam

Thanks for your post. See my reply to Richard as to how I overcame my apprehension.

You are correct in that the shingles and Celotex can take a lot of punishment. Before your post I was wary of putting any weight on them.

Thanks again

Hello, im thinking about buying one of these log cabins…..do you ever get. asked if you could supply someone to build them. im not sure I would manage to do it x

Tuin offers an insulation service as a company, we can also make recommendations of self employed installers who can be cheaper than our services as we have to account for VAT and working hours.

Hi Richard you answered my query that it was slightly over kill for my Blackpool cabin to insulate with 70mm celotex cell with 3×2 then 18mm osb I am worried now about over loading the roof. If I use 5.5 ply will it be ok when I nail the shingles on that they will pierce the insulation beneath? Also what is the best way to join the recycled profiled foundation beams? Is a straight cut with adhesive between acceptable? Thank you for the fast reply’s hoping to start the build tomorrow.

It will go through and into the insulation. That should not be a problem though. I would suggest you use bitumen glue as well for extra security. A straight cut and butt together is normally enough, the first log down can then be screwed to the foundation beam which holds them all nicely. I hadn’t thought of using glue in between the joints, that’s a pretty good idea.

I’m building my Uddel cabin at the weekend. Just checking, if i’m using 50mm celotex, i put the insulation on top of the roof, then the roofing felt directly on top with longer clout nails to fix? No OSB board needed between insulation and roof?

Thanks in advance. Great site by the way, with loads of excellent advice.

Ideally with a flat roof it is best to use a sheet between the insulation and the final roof covering. With shingles it is not necessary as they are so thick but a roofing felt or EPDM is not really thick enough and you will have indents where the sheets of insulation meet.

I’ve a quick question on insulating a floor, or rather a clarification:

This article seems to suggest that if you’re not using floor boards but rather osb then it’s ok simply to not use joists and put the celotex directly on the damp proof membrane and the osb flooring directly on top of the celotex. Is this correct?

Thanks for your time

Yes, in my experience you can put the OSB on top but bear in mind you will need joists to at least join the sheets. You will also need a perimeter fix as we do not want the floor to touch the log walls when it expands. Also, consider any heavy weight such as a pool table, gym stack etc, you will require joists to transfer heavy loads in these areas.

Thanks, Richard. I just wanted to check the details of your reply as I may be misinterpreting it (and please don’t hesitate to call me out on that!).

Why do the sheets need joining with joists? Can they not be joined together just as they would be for the roof? Sheet-to-sheet?

And regarding the “perimeter fix”, by this do you mean having a perimeter of joists a set few millimetres in from the wall to which the osb should be fixed?

Ah, I’ve just realised that by sheets you mean osb sheets! Ignore that question!

You are correct, I am referring to the sheets, it would be ideal to be able to fix the sheets where they are joined. The sheet should not be touching the log cabin walls.

Hi Richard, I’ve just taken delivery of a Ben Clockhouse with a 3.5m pitched roof. I was thinking of insulating but as it has 27mm t&g roofing, will I actually be gaining anything from insulating. We do plan to use the cabin all year round with a log burner. we will also have a hydrotherapy tub in there but don’t plan to use any other form of heating. Your opinion would be welcome.

The Ben Clockhouse Log Cabin is actually designed for the Irish market and is suitable for applying clay tiles hence the extra strength roof.

I would still recommend you insulate the roof, the extra thick boards helps but insulation would be far better. I would like to see insulation both in the floor and the roof. This will make an extremely good all year around building and would not take too much to heat it.

As you have a hydrotherapy tub I would also consider the treatment inside as you will get a build up of damp, I would also advise to fit a couple of vents in the log cabin due to possible moisture inside the building.

Thinking of fitting 50mm celotex, monarfol 300 pitched roof underlay, roof shingles, what would be the best order to do this? Monarfol, Celotex, then shingles? Also would 65mm clout nails hold all this together ok ? Many thanks in advance .

I have never used an underlay when insulating a roof of a log cabin, I know some customers like to, I haven’t had any problem reported either way. 65mm nails and 70mm for the ridge works well with 50mm insulation and the shingles. I did a quick search and the membrane you are using is 0.3mm so it shouldn’t make much difference, again though I have no experience of this so please let us know how you get on. Customers have sent in pictures of the membrane going on first, then the insulation, then the shingles.

Hi RIchard, thanks for your reply, It’s a spare roll of Monarfol a neighbour gave me after roofing his brick garage so thought I would add it into the roof, also I have a deck that I built a few weeks ago out of 6inch x4inch 4800mm board to sit the cabin on and was wondering as regards to a dpm, I have a dpc for under the profiled foundation beams but wasn’t sure wether to fit a 4×3 dpm under my floor insulation to keep any stray water out that may get in from the egde of the profiled beams, would I be better leaving this out so the wood could breath although the wood would get air from underneath or fitting it to protect the insulation from any stray water ingress? Again many thanks.

Thank you for the picture of your base:

As you have made a timber base the foundation beams are not always necessary if it is to the exact footprint. The profiled composite ones do look nice though if you have those and provide a lip over the base which provides a drip and nice profile. If the base is to the footprint you shouldn’t get any water coming through so a DPM is not really necessary. But, it looks as if you base is enclosed, if there is a DPM within it it should not be a problem, if not I would consider adding vents within it to allow for an airflow in the base itself.

Hi guys

I have a Karen on order with 40mm walls my question is can I fit 25mm insulated plasterboards to the internal walls…. Will I have to leave contraction slots on the lower fixing points and a gap at the bottom of the plasterboards for downward movement ??

Thanks

Please see ky article on dealing with a log cabin expansion and contraction which should help your query: https://www.tuin.co.uk/blog/tips-installation/expansion-contraction-in-log-cabins/

Believe insulating under the roof is referred to as cold deck construction. For the void I’ve seen a figure of 50mm but also seen a solution using rock wool (breathable insulation) over rigid foam (polystyrene) over vapour barrier and finally over roof cladding. Think on this blog I’ve also seen someone installing air vent grills into the void. Also seen a YouTube video that showed a simpler installation using multi layered foil insulation blanket tacked under roof boards and then clad. Looked really easy actually though understand the blanket may not be the cheapest material.

Currently stuck on my project so doing more research on this topic then I really should.

Hi Richard,

In the information you give regarding roof and floor insulation, you mention that some people insulate the roof from the inside of their cabins. Although you say that your preferred method is on top of the roof you don’t actually dismiss doing it this way. Leading us to think that it can be done internally. However in the part entitled insulating the roof you then say it causes condensation doing it this way. A contradiction of paragraph one.

Can you please advise us as unfortunately we didn’t realise that there could be a problem insulating from underneath the roof. Sadly we have already felted the roof in readiness for the Shirley to be added. Help please!

Kind regards

Jim & Ann Smith

I always prefer to insulate on top of the roof, this takes all the problems associated with condensation out of the roof. Of course I maybe wrong but it has worked well over the years for me.

You can though insulate inside if you wish to. But, like any building including your house, allowances have to made for the moisture we expel living in it, the appliances we have and the moisture coming from the surrounding atmosphere and of course the ground / base.

Linked above in this article is another article where I give advice on insulating within a building: Dealing with Contraction and Expansion of Log Cabins

The examples given should help to answer your question and avoid a contradiction, if any is found. The main point being to make sure you create a void and to ventilate that void well to allow any moisture to escape.

Additionally insulating on top of the roof saves you unnecessary expense, a great deal of work, additional cladding or fascia and allows full height of the cabin internally. On occasions this is not always possible due to height restrictions. If you are forced to you can insulate under the roof but please make sure the void is vented otherwise, eventually the insulation wall fall down with moisture / water build up.

We don’t really find felt necessary under shingles I do not recommend this personally, if the shingles are fitted correctly and as advised. The felt is only there to protect your building should the shingles blow off (apex roofs). If of course they are fitted as I advise they will not come off. My own, personal recommendation would be to leave the felt as is. Apply the insulation and then the shingles. You may need longer clout nails for this. Alternatively remove the felt completely. If you wish as some people do you can add a breathable membrane between the T&G roof and the insulation although I have not found this necessary either. Then you can add the final shingles. Alternatively, insulate from underneath leaving a void and a vent. What this void depth maybe I cannot advise as I have not done this.

Hi Richard,

To avoid nail so many holes through insulation board when we put nail through shingles and insulation board to the roof board, will it be better put a OSB board on top of insulation board,fix them to the original roof board, then nail the shingles to the OSB boards? I mean for 50mm insulation board. Do you think will it be ok? Also is it ok to put one layer underlay felt under shingles to make extra protection?

Many thanks

Jane

Yes certainly you can frame the roof and then put on OSB or similar of you want to, you can also use an underfelt if you would prefer.

Hi Richard, I’ve just received the composite foundation beams and they sit 10mm proud all around my 100mm concrete base with 20mm gravel outside of this. I want to put in an insulated floor with celotex as you’ve suggested. Do I just put in some floor bearers inside, on the slab floor as the log cabin will sit on the profiled composite foundation beams and then add in the celotex inbetween before using the T&G flooring on top? The tanalised floor bearers will therefore sit on the concrete and would that allow damp to rise into the floor or sides of the cabin? Should I be sealing the profiled foundation beams all around the perimeter to stop any water flow? Thanks. Mark

Once the cabin is built on the foundation beams if you are using them then the floor ban be put in. If you choose to use floor joists these can be laid with the insulation in between them.

It is important though to make sure you have a damp proof membrane in the base or at least on top of it. Please see the information I offer on log cabin bases for examples.

If your base is not 100% level and you have gaps between the base and foundation then you will need to seal this.

Hi Richard, I have just order a Laula cabin without your floor. I would like some advice as to what size joist to put in, at what centers, I would like to insulate the floor ,and also should it be ventilated and how. Mike

Ideally joists will be around 45mm – 50mm in height, this gives you enough room for insulation and sits nicely at the door. Normally I would set these 300 – 350mm apart with an uninsulated floor. If I’m aware of extra weight points such as a set of weight stacks, piano or anything really heavy I will put the joists closer together in that area or provide a direct support.

If you use a board like celotex and have joists slightly below or dead on you can have the joists further apart as the celotex, when supported on a concrete / slab / flat base, can take quite a bit of weight, I would then be considering 400 – 450mm as long as they are slightly below on the insulation depth.

Hi Richard; Lots of great info as usual!

Just took delivery of a Flow Cabin, and was wondering about the following:

a) Using loft style insulation under the (floating) floor?

b) Using same insulation, inside the cabin roof plus plasterboard and therefore any condensation issues?

All much cheaper and similar R values to kingspan/Celotex etc.

c)If I were to use 50mm Celotex on top of the roof, can I fix EDPM directly to it?

Many thanks

Tim Brigg

I’m pleased to hear the flow log cabin arrived safely for you.

I cannot see any reason why fiberglass insulation cannot be used in the floor. I do prefer something like Celotex though as it’s easier to use and handle and does not compress.

I would not recommend at all insulating the roof inside. Condensation can be a big issue, you will need to make sure it is well vented and I cannot give advice on what and how much. If the insulation is on top of the roof you do not ever have to worry about it.

The flow is a flat roof log cabin. It is best to cell the roof with framing and then insulate with whatever material you choose and then put an OSB or similar board on top, then apply the final roof covering.

EPDM or ERM will not be able to fixed directly on top of any insulation. Only felt tiles can do this with at least three clot nails used.

EPDM or ERM is glued onto the surface and I would not recommend it being glued directly to the insulation.

Thanks Richard.

One last question, hopefully;

As we have a raised wooden base, supported on brick columns, is there any need to fix a DPM to the underside of it?

If I do use loft insulation in the floor, I would as it would support the insulation, but celotex would be self supporting as it can fit in snug between the joists.

Thanks again,

Tim 🙂

I think you may as well fix a DPM, damp is still rising from the ground and it would not hurt to do it. If you use celotex you can fix battens either side of the joist to support the panel.

Hi Richard,

Thanks for the help once again.

Cabin up, mostly straightforward (purlins are hard work though!).

Anyway, re your suggestion to construct roof with boards first, then kingspan and 11mm OSB covered in EPDM:

Do you see any problem using the same order of things, except fixing the OSB directly to the top of the cabin, then working in reverse with kingspan next and have the roof boards underneath (between the purlins – a minor faff as they would need cut to size).

This is only to reduce the height a little, and keep the barge boards fixed “downwards” which is my preferred option.

Many thanks

Tim 🙂

I would not recommend doing this as you are then putting the insulation inside the building. This can then cause problems with condensation. If this is the only way to do it make sure you create a void and vent it to allow condensation to escape. My preferred method is always to have the insulation on top of the roof.

Alternate to OSB I believe is marine ply. Think OSB would need to be treated. I believe a google search for warm deck roofs will provide a good selection of articles including one from rubber4roof from which I will be getting my EPDM. They also have some useful YouTube videos to guide you along…

You are correct regarding the Marine Ply. In my experience though I have never needed to treat the OSB. I like the Rubber4Roof site and it is cheaper than us for EPDM, they have a quicker delivery as well for it, I often recommend to customers to try them or even ebay for sourcing EPDM.

Regardless where you get it from EPDM is the very best product to use on a flat roof.

This is a great article and I’m planning on insulating a cabin extension soon. I recall cutting the insulation boards in my existing cabin and found this to be a pain to do. Been watching some youtube videos on cutting boards but great to hear your preferred technique. Afraid, no specialist table saws in my home!

For the OSB boards I will be getting it from the timber supplier but they don’t do insulation boards.

I’m pleased to hear this article is a help to you. The best place for insulation boards is a general builders supply yard such as Jewsons, Travis Perkins etc.

Indeed but they come in standard sizes and I believe none will do any cuts for you like they may for timber.

Thinking I will use my patio chairs as cutting horses, clamp a trim on both ends cut along with a sharpened wall paper remover. Well that’s the theory at least…

I do not know any company that will make the cuts for you. It is easy though, a timber saw or an old bread knife with cut through it easily as will a stanley blade for precision.

Richard I am currently waiting for the arrival of my Justine log cabin and have started to look at insulation for the roof and floor. Is it the Celotex FR5000 that you would recommend?

I normally like the foil back board, it is the Celotex PIR (Polyisocyanurate) 50mm x 1200 x 2400mm. I have recently been told though that kingspan offer a similar board that has higher thermal performance so that maybe worth looking at too.

cheers Richard ill look at this too

Hi there, I have an Eila on order and am just finalising the insulation. I am using 50mm foil backed boards (celotex or similar). Can I stick EPDM direct to the insulation boards or will I have to board over the celotex with some ply or osb? Thanks, Tim

If you have a flat roof is is far better to frame it and put OSB or similar on top with the insulation inside. EPDM or the Roof Membrane will not stick well to just the insulation board.

Hi I have just order foil board insulation for the roof . I have gone with 60mm and was intending to fix direct to roof and the the fix the shingles … I have just read down this post and see you have started to talk about framing and osb if the insulation is greater than 50mm. Do you see any issues if I don’t frame it with the 60mm board

Regards. Jonathan

When you go over 50mm you’re asking a lot of the nails holding that depth of insulation, Also I’m not sure if you can get nails long enough. I would not use anything above 45 – 50mm thick insulation without framing and boarding the roof to make sure there are no problems.

Of course though, it may well be fine, but it is not something I have done or could recommend.

I’ve just managed to insulate and shingle one side of my Lotte roof but it’s now raining overnight and is forecast to continue tomorrow. The completed sides of the celotex (it’s not actually celotex but recticel, basically the same stuff) are exposed to the rain. Will it be ok?

I remember fitting a huge building that took over three days to finish the roof, it was the height of winter and during those three days we had snow, slush and rain on the roof with exposed celotex and it did not come to any harm, I have not used your make of insulation but I would imagine it will be fine if it is a similar material.

Thanks Richard. I got out there again this morning after a night of heavy rain and it was indeed absolutely fine.

Thank you for letting me know. There is not a lot you cannot do in the inclement weather.

We have a log cabin that uses 6 foundation beams that run in parallel rather than around the perimeter. If we were to insulate the floor then the insulation would be exposed at the edges. Is this okay or could water be soaked up through the insulation and into the floorboards? If I were to cover the gaps between the parallel beams would I need to put ventilation holes in?

Other suppliers do things a different way, I do not see why they use parallel beams and would suggest our method of a ring beam every time. But you have to make sure the base is to the footprint of the building and that it is flat and level. This will create a natural seal. A layer of DPC also helps with this.

If you have parallel beams you will need to seal the edges, I would suggest infilling with timber the gaps. Make sure though your base is sealed. In extreme infested areas such as farms I have known customers to lay chicken wire in before applying insulation.

Ventilation holes are only necessary if you expect water within the bearers caused by not using a DPM or a bad, none sealed base.

Some of the videos I’ve seen show people fitting a wooden frame around the cabin roof and then fitting the insulation boards inside this wooden frame, would you recommend this? My concern is that if the insulation is open to wildlife on the side elevations of the ‘Royal Two Log’ cabin they may burrow in to it or peck at it and damage the insulation.

The Royal Two is an apex log cabin. If you are using 50mm or less then the side elevation and also the apex will be covered by the boards at the side and front and no entry should be made. You may though need to source slightly wider boards for the leading edge locally.

If you are putting in thicker insulation then it is a good idea to cell the roof with framing and then a sheet of OSB / ply on top of that. The final roof covering would then attach to that.

If you have a flat roof log cabin then is is also necessary to insulate in this way as the final roof covering will be felt, EPDM or roof membrane which cannot be fitted like felt shingles.

The leading edge and apexes would finish as normal.

My log cabin has an apex roof. I was planning on using some 40-50mm insulation on the outside as previously mentioned and then put some good quality felt over the top. I notice though that above you say that would not be possible with felt only shingles. Why is that?

If you are using shingles these are very hard to fold over flat due to the thickness of them. Felt is far thinner and can be folded easily and trimmed. If you need to cover exposed insulation you can use a timber trim on the leading edge which is usual or raise / wider barge boards on the apex. But, if you wish to use felt under the roof shingles this can then be folded over. I have seen some people use this method OVER the leading edge trims as they will eventually rot as they are exposed and a felt folded over will protect them.

Thanks for a very informative site:Regarding insulating the floor i have ordered a 27mm floor pack for my Stian which will be sitting on the composite foundation beams.I was wondering as the joist are 44m and fitting 50mm insulation will this mean that the boards will sit on the insulation with a 6 mm gap to the joists below.I was considering blind screwing using Lost-Tite Screw however will this not distort boards when fixing ?

If you are using 50mm insulation you will have a gap between the joist and floor board due to the joist height. However, the insulation we recommend is load bearing and the floor boards will sit directly onto this and supported by the insulation board, the joists are only there to secure the boards to and carry no load.

I have not noticed boards distorting when nailed but I have not used the fixings you are referring to.

Alternatively a thinner insulation can also be used.

I had the same concern when insulating my floor so I used 40mm celotex instead of 50mm just to make sure. However we are not planning on using the cabin in the depths of Winter so the slight decrease in insulation shouldn’t make too much difference.

Thanks for you website – info is soooooooo helpful.

I have a question about your method of insulating the roof – why do you not need an air gap between the insulation and the roofing material? Will condensation not then build up around the insulation and eventually cause the roof boards to rot?

Condensation can become a big problem when insulating under the roof boards, when it is on top I have never had a problem as the moisture build up is inside the building not on top of the roof. It’s been nearly twenty years since I have been doing it this way and I have not had a call back so far. But, I maybe wrong and others may have a different viewpoint or thoughts and I would be pleased to hear them if anyone thinks my personal method is wrong.

I’m more than happy to go with your experience – thanks for the reply.

How would you insulate the floor if building on a timber base? Confused were the DPM would sit, and if you put the insulation in the bottom frame, or if you need to build a further frame on top to add insulation & flooring?