This covers some much needed clarity on our pressure treated garden timber.

Earlier this week we received a review on one of our products, part of it was:

“The first thing I noticed was how badly it had been pressure treated with green splatters on a number of pieces”

I personally really hate a bad review. this was one but unfounded. We try our hardest providing a top quality product with a top class service and will review everything requiring improvement where we can. Sometimes though it just comes down to understanding a product that you are buying and the expectations that match it.

This review has prompted me to write this quick post as from this statement it is clear that customers are not realising what tanalised timber actually is: I shall explain a little about it so people can gain more understanding of what you are buying and that there are no faults at all nor “badly” carried out.

Tanalisation / Pressure treatment are one of the same, it is the identical process and is carried out normally on pine timber for outside use as a rot protection:

Terms

The two terms used are describing exactly the same timber treatment:

- Tanalised is actually a trademark, as is ‘Tanalith E’ which you will see sometimes. This brand has been around since the 1940’s.

- Pressure treatment is the process carried out using ‘Tanalith E’ or similar.

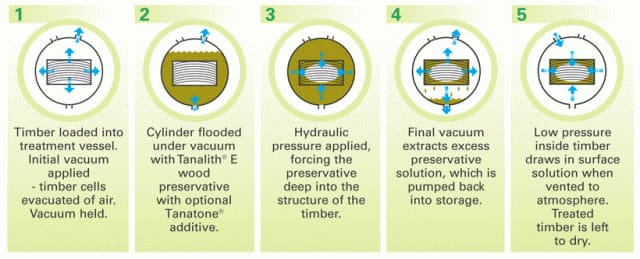

Process

The treatment process is carried out by placing the timber in a big tank. The door is shut and a vacuum is created inside it. Then the pressure treatment fluid is allowed to enter and is forced in the wood under the pressure. It penetrates to a depth of a few millimeters.

Ingredients

The main ingredient is copper with other chemicals added. Copper is excellent for protection against rot and insects. The other chemicals (Biocides) protect against other rot that the copper can’t such as ‘brown rot fungi’. These substances are not harmful at all and can be used around animals and children. Fish may be sensitive to it.

Rot Proofing of Timber

It does exactly what it says and protects the timber from rot really well, internally they say about 60 years and externally about 30 years against any form of rot. It’s pretty good stuff!

Promotional video explaining the Tanalisation process / Pressure Treatment

Limitations of tanalisation / Pressure Treatment

So now we understand how the process works, as the video explains, the timber will be:

- An initial light green colour.

- Weathers to a light honey brown.

- Eventually to a natural silver grey.

This change of colour is not any indication of loss of preservative protection. Subsequent decorative finishes can be added to create the look you desire, you will see many examples of this across our website and catalogue.

We supply fixings that will have a comparable life to the timber for many of our products but please note if timber is cut, notched, sawn etc then a comparable treatment will need to be applied to carry on protecting the timber.

Perceived Faults in Pressure Treated / Tanalised Timber

Occasionally, a customer will perceive faults in the process without a full understand of it such as the above review. Some of these perceived faults are:

Formation of salts:

With impregnated wood it may seem as if salts are formed on the surface of wood. It is actually resin that colours yellow/green due to the impregnation. These stains will vanish in time. This is an example and shows the ‘Splatters’ complained about in the review:

One of our fence panels displaying the formation of salts and “Splatters”

You can see from this picture green portions on the fence panel. We cannot help this as it’s part of the pressure treatment process. You may see this on your new pergola, planter or gazebo, please expect this, it is completely normal.

Fungi and blue moulds:

Blue mold and the formation of salt crystals.

Other faults

Light bleaching after the tanalisation process.

Well explained and very helpful. Thanks for sharing.

I have received very dark green softwood railway sleepers. How long does it take for these to fade down to a honey colour? I assume these are very freshly tanilised – arent just a pale, hint of green at all.

They can take a while to change, it does of course depend on the weather, time of year and season.

Great article I was about to complain and ask for a refund from the company I bought it from.

Clearly written and really helpful. I also was thinking I should sand down the wood to remove the green marks. So glad to know I don’t have to.

As a complete layman I’m grateful for such a clear explanation and straightforward video. Thank you, especially for saving me from rubbing down my new softwood garden gates.

Hi

If I plan to install a cabin in the winter months, is it advisable to get pressure treated? And would the cabin then be ok to leave until the better weather to treat with a decorative/protective coat?

I have installed 100’s of log cabins during the winter and none have come to any harm, I personally do not recommend pressure treatment for several reasons already mentioned. The slight downside of treating in the winter is that some treatments need a temperature above 5 degrees. There are though lots of nice days in the winter and it should be possible to apply at least one coat.

Thanks you have put my mind at rest, I can now go and buy my garden swing seat with a peace of mind. 🙂

Precise, thorough and helpful – thank you!

I have a client who wants the timber pale and weathered NOW is there any way I can speed up the disappearing process?

Sorry, I’m not aware of any way to speed up the process of weathering.

Blow me down! I was already in my shorts, ready with the sander, to go out a smooth off all those pesky crystals and green bits prior to decorating a lovely new palisade fence …

Thanks for saving me a wasted afternoon, and for saving my brand new TANALISED fence!!

Very useful – clarified a lot of issues which I now don’t have to worry about!

This was really helpful. Thank you for posting.

Thank you for this post, very reassuring and easy to understand.

Great informative post. Thanks. I was wondering if its OK to apply finishing products (stain/oil) before the tannelised stains disappear?

It is best to leave it for a few weeks once installed to weather and make sure it is dry for freshly tanalised timber. After that it benefits from a waterproof treatment to further protect it from the elements and to keep it looking good. This is important in the case of log cabins and sheds.

Brilliantly helpful. Clear, informative and reassuring. Thanks :o)