If you’re looking to buy a log cabin and are looking for advice, if you take nothing else away from my blogs and ramblings please at least read this one and check with your log cabin supplier they use these log cabin joints.

We’ve got something we call Wind and Watertight Connections in the corner where our logs interlock. They’re pretty much the standard these days for any good manufacturer of log cabins as it is really very bad not to joint using this system or a variation of it.

It’s not something we shout about and nor do many other companies who use them as it should be a standard feature.

Not using a W&W joint leads to lots of problems in the future for the log cabin. It does though save the manufacturer a lot of money in machining costs and machinery.

No one in the UK would be that cheap to save on manufacturing costs, would they?

Promotional Video on Log Cabins

I saw a promotional video on YouTube recently from a prevalent internet only retailer.

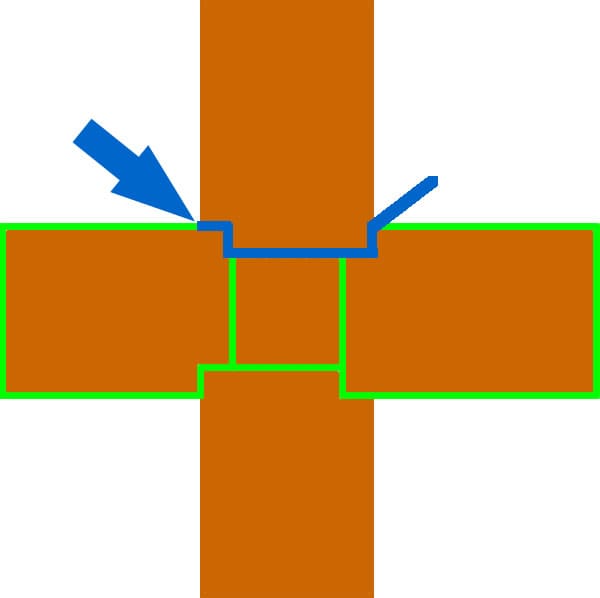

This is a screenshot from their video:

Heavily advertised and prevalent retailer on the internet selling log cabins. This is a screenshot from their promotional video on YouTube.

You’ll be looking at this and I bet you don’t see anything wrong with it, it looks like a log joint you’d expect doesn’t it?

Wind and Watertight Connections for Log Cabins

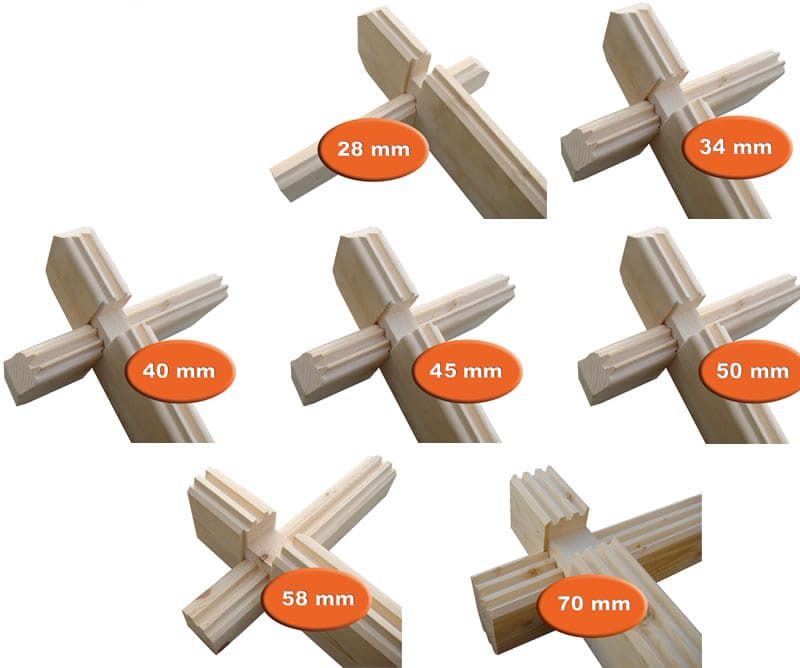

These are our logs with a wind and watertight joints at the corners, look for the second offset cut that we make. Other good manufacturers of log cabins will also use something similar.

Wind and water tight connections on all logs except 19mm. Wind and watertight connections on all 90 degree corners. This connection though is impossible to use on angled logs.

Here’s an exploded view, compare it to the screenshot above.

Wind and watertight connection should be present in all Good makes of log cabin, it’s made of a second offset cut each side of the main notch.

Straight route for wind and rain

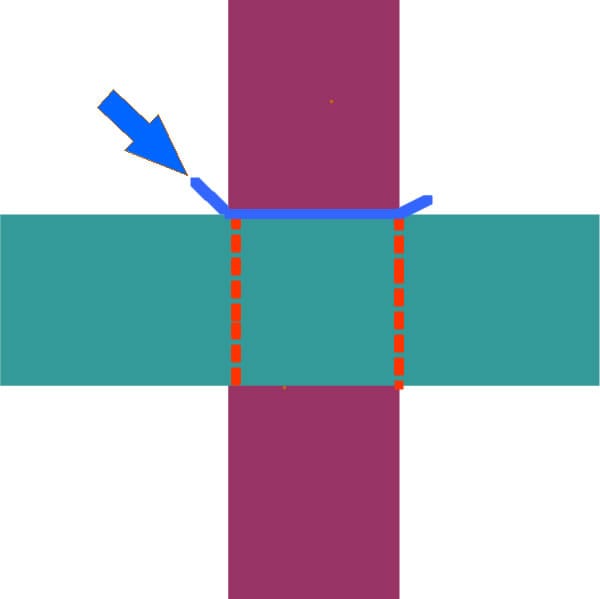

Here’s a diagram of a log connection that doesn’t have the second offset cut:

With this connection there is a straight through route for water and rain. This is done to save manufacturing costs.

Using just a straight through connection you run a very real risk that when the log shrinks further as it will do in low relative humidity you WILL have problems guaranteed.

You can expect to see gaps appearing which will allow rain or wind to come in to the joint. More Information: Relative humidity and moisture content in log cabins.

Now we’re not saying the W&W joints are impervious to leaking ..”ever”.., but they will severely minimise the probability of it ever happening, You will still need to fully weatherproof the joints with the decent application and type of Treatment

Highlighted Problems with straight cut

This screenshot is from the same promotional video and is clearly showing a problem starting with this cabin

A gap is starting to form in the log, this is down to bad machining and no W&W connection. This is also a sign that the wood had too higher a moisture content level when it was milled

Wind & Waterproof offset connections

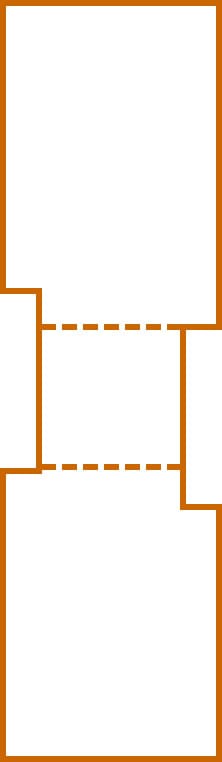

This next diagram shows how the log profile will look with a wind and watertight connection cut into it, notice the second cut that is made apart from the main notch cut. The second cut is offset.

Showing the cut of a wind and watertight connection in a log cabin wall log

Of course this is not to scale but you will get the general shape and idea of the connection. The machines that make these cuts are not cheap. If the factory does not have them it means they have to process this log twice. This adds to the manufacturing costs.

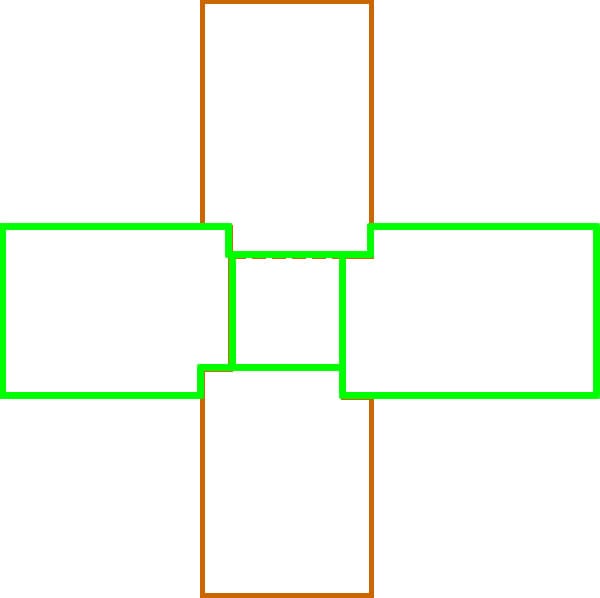

This diagram shows two 90 degree logs connected together. They’re highlighted so you can make out the paths, it’s quite a complicated joint when you study it.

Logs connected with a wind and watertight connection milling

Difficult for WInd and Water to find a route

This last diagram shows the path the rain or wind would have to take to get inside the cabin.

Weather path is highly deviated

See that the path through is highly deviated. With logs dried to 14% – 16% and then machined with this joint it is unlikely anything will get into your cabin regardless of Relative Humidity and especially if you treat your log cabin correctly.

Please watch out for this. My strong advice is to check with your chosen supplier what joints they use in the interlocking corners. The alternative is to buy something cheaply made, which will cause problems in the future.

Please Note: You will only find these connections on 90 degree joints, no manufacturer is able to make them on angles so for corner cabins it is very important the wood is milled with the right moisture content in the wood for the UK market. You will also not find these on any 19mm log cabins as making this connection will make the actual log too thin at the joint and would easily break.