Timber – A bit of a pain

Cracking and Splitting of Timber is a complete pain for our industry during the summer. It’s at this point we get customers questioning the ‘quality’ of our timber used in some of our products as some cracks and splits start to appear in items that use posts such as play equipment and gazebos.

Thankfully, it’s not just us either, every single supplier of timber products for the garden gets exactly the same thing.

Summer historically costs the timber industry thousands upon thousands of pounds due to perceived ‘defects’ in timber by customers when 99% of the time no defect exists at all.

Natural Organic Substance.

Timber is a natural substance, we all know that. As a living organism, it is influenced heavily by its surroundings. More specifically it is trying to reach an equilibrium with it’s natural surroundings.

Water Content.

When a tree is first cut down (green wood) it can contain over 50% of it’s weight in water. This water is naturally contained in the wood and is divided into two categories:

Free Water and Bound Water.

Free Water is water that is held within the wood via capillary action. It can be absorbed and expelled.

Bound water is water within the wood that is bonded via hydrogen atoms.

When timber is dried it will be the free water that is the first to leave.

Before timber is used it is dried when most of the free water is removed (fibre Saturation Point of Wood (FSP)) FSP is achieved at about 25 – 30% moisture content. Wood is dried to it’s natural surrounding environment and as such is engineered to work within it to about 20 – 25%.

Benefits of dried timber.

- Decay organisms generally cannot thrive in wood with a low moisture content. Many wood loving insects can only live in green timber.

- Dried wood has better thermal and insulation properties.

- Preservatives and finishes penetrate better with dried wood.

- Dried wood is generally a lot stronger than green wood.

Equilibrium of the environment

As I’ve mentioned wood wants to be the same as it’s environment both in moisture content and temperature. This is where we start to see a problem, especially during the Summer months and soaring temperatures. The timber starts to exhibit cracks and splits where it further dries out from it’s original point of FSP.

It is, by its nature trying to reach an equilibrium with it’s surrounding air moisture. During summer this moisture content in the air is going up and down all the time as is the temperature and the wood is trying to do the same thing.

Seasonal Wood Shrinkage.

Regardless of how well dried a piece of wood is it will always grow and shrink according seasonal changes in relative humidity of the air.

Any change in ambient humidity will affect timber regardless of any other factors.

A good treatment can slow this process down greatly regulating how fast moisture gets in and out of the timber. Wood shrinks by different amounts in different directions, there is however very little movement in the grain lengthwise. There is some shrinkage radially and a greater amount tangentially (along the curvature of the growth rings).

Here’s a picture of my gate post at home, the weather we’ve been having is having a major impact on it. You’ll notice that cracks and splits are appearing and will continue to do so at different rates. Most of the splits are occurring perpendicular to the growth rings because there is more shrinkage along the direction of the rings. At the moment this piece of timber is still drying to reach an equilibrium with it’s surroundings, the inner core is wetter than the outer but once that has dried to the level of the atmosphere virtually all these splits will dissapear.

Examples of Timber Cracking

Here’s another basic but extreme example. Because of the different rates of radial and tangential shrinkage, distortion of the wood can occur. It can also cause radial cracks from the centre of the wood to the outer edge. This is because the circumference shrinks more than it’s radius and a big radial crack appears allowing the circumference to shorten.

Here’s my post again showing a crack top to bottom, this is a radial split as above and will close up once the whole of the post has reached an equilibrium either by further drying or expansion as the moisture in the air increases such as Autumnal weather.

Here’s another example, this is a crack that’s just starting to emerge, they can appear very quickly during a hot day and often after installation if exposed in the hot sun or stored in a hot environment such as a garage.

The same thing happens to furniture when out in the sun or a change of humidity. This is the timber from my picnic table I photographed yesterday, you’ll notice small cracks are just starting to appear.

Round poles such as the type used in many play centres, swings and climbing frames also exhibit the same properties and often far worse:

What is mainly affected?

The properties exhibited here are mainly found in products that utilise posts such as our gazebos and outdoor play equipment.

Due to the fact that the posts are made from whole tree trunks, this is the case. You can see that very clearly with my fence post as an example, this was not supplied via Tuindeco but by a local fence supplier, our posts however will be the same. This post has been in the ground for about 12 months and supports a gate. This post is encompassing both the ‘Heart’ and the ‘Pith’ of the tree and as such it shrinks and swells at different rates. A whole tree trunk is used as it is considerably stronger than the outside of the tree, If we were to use the outside then we would lose a huge amount of strength, the strongest part of a tree of course is the heart.

Summary

As I’ve said and we all know, wood is an organic substance. It also tries its hardest to match it’s environment which you may not know.

It moves, swells, and shrinks to do so and is normal timber behaviour.

This should be fully understood and expected when buying any timber product for your garden. Sometimes these cracks can open up alarmingly large but remember it is entirely normal and once the inner core has dried the crack will close up. Likewise as the moisture in the air increases so will the free water absorbed by capillary action in the wood and once again the cracks will close up.

None of these splits or cracks in the timber will affect it’s structural integrity or inherent strength.

If however, it concerns you I recommend the use of a good quality timber treatment as this will restrict the moisture both entering and leaving the wood.

Basically timber can be viewed as a bit of a pain!

Customers sort through the DIY shops, they buy gazebos or other ‘post’ style products and immediately reject them as being defective, this is simply not true!

Wood, by definition cannot be defective, there is nothing to go wrong other than obvious rot which is very rare in graded timber.

If you experience cracks and splits in your timber, especially when it is obviously milled from a whole trunk it is not a ‘defective’ product, nor is the strength impaired, it simply is timber exhibiting it’s normal state and characteristics.

If you don’t like it, treat it with a good timber treatment and restrict the flow of moisture in and out. However! Even the best treatments allow moisture transfer, even plastic does to a certain extent.

A personal Experiment with Cracks in Timber

Update: 11th August 2013

I’m going to try and prove my own waffle, I’m going to focus on my fence post, bear in mind it’s been in the ground for about a year and I’m now going to try and study it.

I plan to photograph it over the weeks, months and maybe years ahead. It’s all very well me spouting on about the theory. Some may even see it as excuses for a dodgy bit of timber so lets actually see what happens with this post over time if at the end I’m a liar I apologise. This is going to be interesting ….. as far as a bit of wood can be …

I’m also going to find a brand new post from one of our Gazebos, stick it in the ground and see what that does as well, for now, my fence post …..

Updated picture, today, 11th August 2013

Some of the radial lines looks smaller to me, or am I just imagining them? The split at almost 12 o’clock is smaller.

There’s changes but nothing has really closed up.

The week’s weather has had some rain, a couple of storms but not massive amounts, it’s still been pretty warm. Lets see what the next week or two does to it.

The next time I’ll keep the camera back like the picture above so we can really see the changes ….. if any … or at least compare them better.

Update 29.10.13

A huge change since the last time I looked at the post. You can really see the change this time and most of the splits have closed up. Both the heart and the pith are reaching an equilibrium. Clever stuff wood!

The splits that were showing in the side of the post have almost gone as well.

Timber splits in Construction

I enjoy looking at the properties of timber, it fascinates me how it moves twists and turns yet remains the exact same strength.

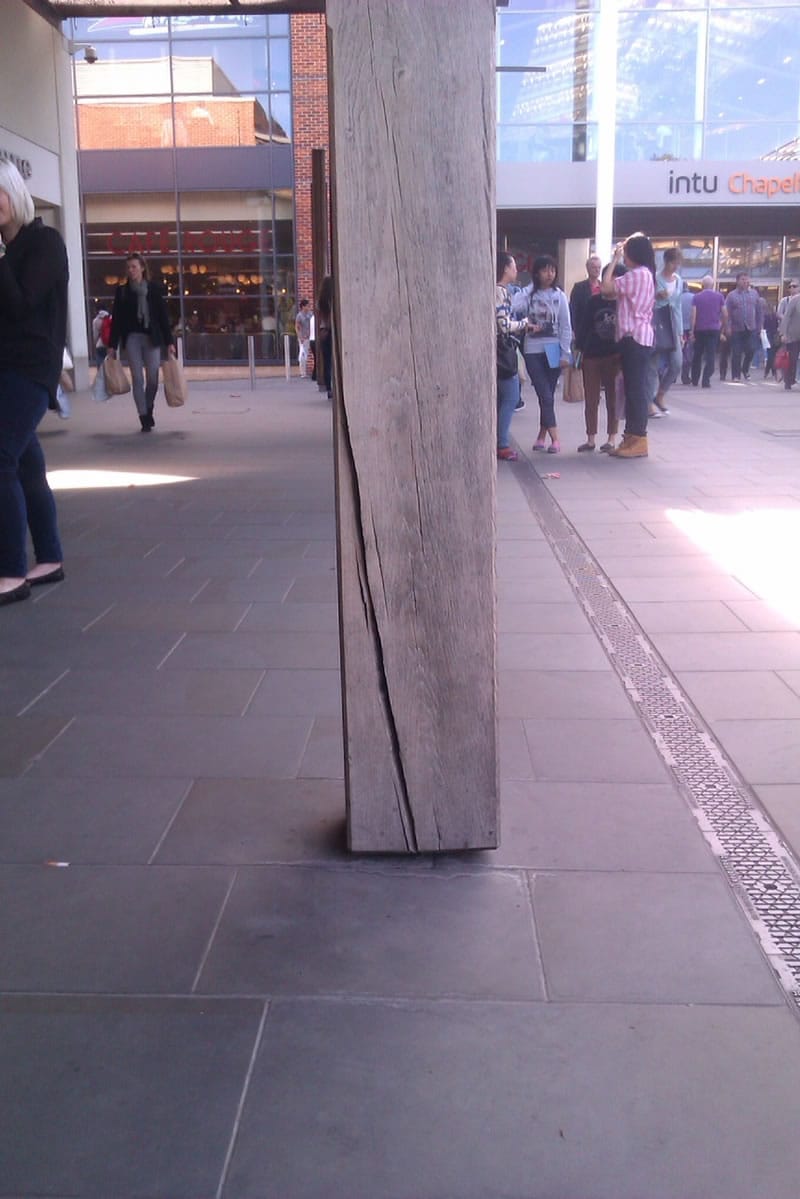

On a recent trip to a city shopping center it tickled me to see this split in a main supporting post.

Amazing stuff timber! This isn’t defective. It’s not a problem and its strength is not at all affected. I hope not, as it’s supporting a massive canopy in the cities new shopping centre!

Update, 11.10.2018

One of our employees had recently returned from a long weekend away in a log cabin – Lucky for some, I know. Although the Log Cabin she has stayed in is seen as a ‘traditional‘ log cabin, meaning that they mostly use rounded/half round logs in their construction, the timber is similar. Just like almost every type of timber you’ll find, there will be cracks and split, but it hardly affected its use for our employee’s holiday!

She writes as follows:

“So thought this might be of interest, I stayed in a pine log cabin over the weekend and you should have seen some of the splits in most of the logs… I’ve attached some pics, it was interesting to see. (The pics aren’t great, sorry).”

I think that the pictures show more than enough to prove that even with cracks the log cabin is still standing strong. It is more than suitable for the accomodation purpose it provides!

I have experienced shakes in timber on fence posts and our play area, both lasted more than 20 years, however both were pressure treated. My concerns are with my log cabin that was treated with Embardecor inside and out and 2 coats of Embalan on the outside. Both are surface treatments so the large shakes I have in my cabin are exposing untreated wood to the atmosphere.

Hi Ray

Thank you for your message and i understand the concern, Timber can be a pain sometimes and somewhat annoying when a split appears on a treated surface. We have never known it to be a problem as they tend to close back up come the wetter months.

However for peace of mind you can always go back over any new splits with a brush to add the protection now missing. Just be mindful not to clog it up fully

Hope this helps, Ben

Just bumped into this and found it incredibly facinating to read. I am building a porch with Larch as it was recommended by our local timber suppliers. I had it delivered last November, horrid weather and stored it in our garage. I have put the base bits in and noticed some cracks appearing in the wood. Great I thought, have to fill those, before putting a coat of somthing on them. This article as absolutely made me smile and saved a shed full of work on my end. What a knowledgable read, my posts mounted on top of a low wall are 150mm x 150mm.. man posts to say the least and great to work with by the way. I had no idea that Larch was such a long lasting wood either, 60 years un treated or a 100 treated! Given me an exta zip in life.. perfect.

Thank you Mark for sharing and we wish you well with your project!

We have a second story deck and are replacing the floor boards after 20 years. My wife and I were extremely worried about the large cracks in the supports and were worried that we would have to replace the entire deck to ensure its integrity. Your article puts my mind to rest and we look forward to 20 more years of enjoying the deck (once I get those floor boards replaced–ugh!). Thank you for the article!!

Really interesting and informative article, makes perfect sense! Timber is such a nice material, so good to understand it more.

Great explanation and certainly calms the panic of seeing such splits. I do have a question though,…

I have treated the outside of the cabin as recommended, but have done nothing with the inside. With the temperature changing from as low as 0 ( or minus as of late ) up to late teens / early twenties inside, should I be considering some sort of treatment in the inside of the cabin or just let the wood do it its thing ?

In a perfect world we’d treat all of the timber but time, resources and aesthetic may prevent that. As a minimum though it’s highly recommended to treat the doors and windows all over, inside and out.

Really helpful information Richard. I built a decked terrace last October and have noticed lots of splitting now that the weather has got a lot warmer. Great to know that there is nothing to worry about! Genuinely interesting read too! Thanks, Tim

Thankyou we retrieved a whole tree trunk from our local river and installed it as decorative shelving(it runs floor to ceiling in the corner with a four shelves attached to the wall and trunk) I knew it would split a bit but was starting to worry that it would end up clear in half with how big the splits are getting you have helped to ease my mind

Alright Richard,

Just read up on the cracks and splits in oak beams and it’s answered a lot of questions that we had after we built an Oak frame last year and started to worry about the splits and cracks that have appeared.

I will monitor them over the coming months

Cheers

Hi Richard – what is your opinion on 44mm v 70 mm for an all-year-round cabin. I was going for 70mm but have been advised 44mm is fine if the roof and floor are properly insulated and that 70mm gets a lot of splitting in it. If is the case about 70mm splitting, does this eventually resolve itself when fully dried out?

In my view the thicker the logs the better it will be. But, of course this also comes down to budget which makes a 40 – 45mm cabin a good choice. I haven’t noticed much difference in splits in 70mm – 120mm as there are in the smaller logs.

Hi Richard, we just recently put oak stairs in and there are radial splits appearing along some of the threads. In your article you refer mainly to outdoors but is this also normal behaviors for indoor oak wood products i.e. thread on the stairs?

The same applies indoors, sometimes more so as we keep our homes so warm. Indoors fluctuates quite a bit and timber can suffer. I have some oak frame and beams in my house. When it first went in everything was smooth, now on some timber the cracks are quiet huge at certain times of year. Other times the wood closes completely, generally this is in the colder months when the air moisture content is higher.

Examples of some of my cracks currently (end of April):

I can’t comment specifically on your stairs as I have not seen them, please send a picture (s) to the main office – info@tuin.co.uk and I can comment further but certainly you can see cracking and splitting of timber indoors as the temperature fluctuates and the wood increases and decreases its moisture content.

Superb article! You saved me from filling&ultimately creating a mess of my beautiful solid oak dresser! I will age alongside it – although probably not as gracefully;)

Nice read. I have been looking for good sources about oak timber and other stuff that will help me in my DIY wood projects. Thanks for sharing a very informative post which I will definitely share with my friends.

Hi Richard, I recently put a large porch post in, not knowing too much about Oak and used a light wood preserver on it Cuprinol fence for life should I have done this? The post is cracking and a little splitting…Is this drying out. Garry

Oak is a lovely timber and can be left entirely untreated, much the same as larch. Some people like it to weather naturally, exposure to sun light will allow it to weather to a silvery colour, prolonged exposure to rain will result in a blackened look. If you want to keep the natural look of oak or larch you can apply a good quality clear treatment.

However, regardless of a treatment the wood will still naturally dry during the months of low relative humidity, likewise it will expand in higher seasons (Summer / Winter) At the height of summer your post will have a very low moisture content on the outside and it is highly likely it will crack and split. This is rarely a problem at all and the strength and integrity will remain. As we go into Autumn and Winter the wood will absorb moisture again and the natural splits will close up.

Really useful – was just about to start filling cracks in my 10 year old pergola to stop water ingress and rot! – would like to have another look in autumn (we are in a particularly dry spell right now) I think filling will look a mess and take away the charm. Thanks Richard

Great post , just googled timber splitting & has given a great explanation .i was just wondering do the dynamics remain the same with timbers inside your house ? We are doing a barn conversion & as you can imagine weird & wonderful colours & shapes . We have have had put in a solid chestnut swept block staircase which looks self supporting ,it was installed May last year 2016 & there are some real large cracks . Do we take it that the principle is the same ?

Many thanks Andy

Yes, it is exactly the same principle, timber will still contract and expand according to the temperature and humidity within the building. You will most typically see this in barn conversions due to the exposed timber.

Hi, Excellent article. We sell garden gyms and use treated pine and green oak. We often get customers rejecting one or two posts because of cracking and have to resend different posts. This article is great to show people that it is visual not structural. Keep up the good work. Regards

Luckily I have read this and get clear idea of y timber having splits.

Can I just echo the comments above – I work for a building company and our clients have complained in the past about cracks in timber we’ve used in the gardens and I’ve never really known what to tell them. Other than that our long-in-the-tooth carpenters tell me they don’t have anything to worry about! How refreshing to find someone who is so enthusiastic about timber that they are willing to share their knowledge in such an accessible way. Thank you – I now feel much more confident in speaking to clients about this!

I thoroughly enjoyed reading this , I only logged in to see how to treat a splitting wooden step . Half an hour later . It is so interesting and infectious you want to spread it around.

I’ve just put up a timber tepee with timber poles in my garden and must admit to being a little alarmed at the splits that have opened up in the poles, however reading your post has really reassured me and taught me a great deal about a fantastic material, the concept that it is still ‘alive’ is fantastic. I have coated it in a timber care protector , I wonder what’s the best way to prevent rot ? Regular coating particularly at the bases which are constantly in contact with the ground. Thanks for your time and advice, very much appreciated

Hi, Thank you for your comment, people forget that wood is a living product, especially when they see splits and then panic but they need to give the timber a chance to reach the same moisture content throughout, then the split or crack will go. It’s clever stuff.

I like the black tar for a post that is in constant contact with the ground although for tanalised timber this is guarded against to a certain extent.

Fantastic explanation and even better explained with the pictures – we get a lot of people asking about this in the summer so handy to point them toward this!

Richard, your love of timber appears both genuine and infectious. It will probably persuade me to buy your product, more than any sales pitch could!

Well explained Richard. Spot on!